User Manual

52 Pages

Preview

Page 1

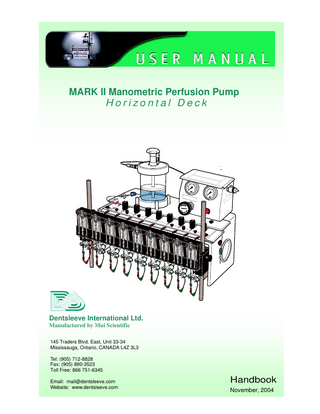

MARK II Manometric Perfusion Pump Horizontal Deck

Dentsleeve International Ltd. Manufactured by Mui Scientific 145 Traders Blvd. East, Unit 33-34 Mississauga, Ontario, CANADA L4Z 3L3 Tel: (905) 712-8828 Fax: (905) 890-3523 Toll Free: 866 751-6345 Email: [email protected] Website: www.dentsleeve.com

Handbook November, 2004

In

Index

Section In

Index

Section A

Overview

A-1 A-2

Schematic of pump Major pump components

Section B

Precautions & Warnings

Section C

Normal Use

C-1 C-2

Assembly & filling of perfusate reservoir Check, connect & set air supply

C-3 C-4 C-5 C-6 C-7

Connection & flushing of water manifold Check flow values of each hydraulic resistor Turn on water perfusion to fill each transducer Transducer calibration (if required) Connect catheter to transducers

C-8 C-9 C - 10 C - 11

Water injection procedure - each channel Check flow value for air perfusion manometry Observation & refilling of perfusate reservoir Maintain correct perfusate reservoir pressure

C - 12

Prevention, recognition and correction of hydraulic resistor blockage

C - 13

Compressor

Section D D-1 D-2 D-3 Section E

Steps on completion of measurements Perfusate reservoir Water manifold Air supply Set Up Procedures & Connection of Components

E-1 E-2 E-3

Air supply/compressor Perfusate reservoir prior to first use Installation of pressure transducers

E-4

Water perfusion manifold – removal

E-5 E-6 E-7

Standard hydraulic resistors Compact resistors Air perfusion circuit

2

In

Index

Section F

Cleaning & Disinfection

F-1 F-2

Cleaning of plastic parts Sterilization of perfusate reservoir

F-3 F-4 F-5

Sterilization of manifolds Hydraulic resistors Cleaning of compressor

Section G

Regular Maintenance

G-1

Every 3 months (or as needed) : perfusate water filter

G-2

Every year (or as needed): gas filters

G-5 G-6

Service of control box by Dentsleeve Compressor dessicant

Section H

Problem Solving

H-1

Diagnosis of abnormal Air consumption

H-2

Abnormal Air consumption - perfusate reservoir leakage

Section I

○

○

○

Specifications, Support, Spart Parts & Accessories

I-1

Specifications

I-2

Support

I-3 I-4 I-5

Spare parts Parts List Regulatory information

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

Notes on the use of this manual • References within the manual are shown in brackets eg (C – 4.2) = section C, part 4, instruction 2 • Part numbers (#) given in the text are unique for Dentsleeve • The technical information and illustrations in this manual reflect specifications and operating procedures at the time of drafting. Some specifications and operating procedures differ from earlier manuals for Mark II perfusion pump models. Dentsleeve reserves the right to vary specifications and operating procedures as part of its continuous product improvement process.

3

May 2003

○

○

Overview

Schematic of pump

100 kpa or 15 psi

A A–1

Regulated Air Supply to perfusate reservoir

Water Perfusate

Air Supply

Pump control box Perfusate Manifold

Manifold Purge Clamp

Manifold side-arm pinch valves or pinch clamps

Hydraulic resistors

3 Way stop cocks Pressure transducers Catheter connector tubes

Catheter

Note: Schematic diagram of water perfusion circuit. Only critical components are shown.

May 2003

4

A

Overview

Major pump components

A–2

Perfusate reservoir Pump control box Reservoir pressurization line

Reservoir outflow control device

Air supply gauge Manifold cover Air inlet

Pinch valves

Compressor connection plug

Compressor on/off switch

Main deck

Pinch valve or pinch clamp deck

Pressure transducer rack

Manifold flush pinch clamp Standard hydraulic resistors Transducer rack slide

Note: Pump length, channel numbers and spacings vary according to individual specifications. Compact deck version shown. Transducer types vary.

5

May 2003

!

B

Precautions & Warnings

B–1

!

Only pressurise reservoir with this line (C – 3.1).

! Air perfusion channel. Only use for pharyngeal swallow monitoring.

!

!

Never drop. Do not use if visible damage.

!

Air Pressures never more than 300 kpa (45psi).

Water level never less than 2cm (C – 10).

May 2003

6

C

Normal Use

Assembly & filling of perfusate reservoir C – 1

Note: See E – 2 for Dentsleeve part #’s Fill with particle free, degassed, distilled H20

1

2

Add water, then place perfusion float barrier on top

Blow-off valve

Perfusate outlet hole

‘O’ ring

Reservoir outflow control device

! !

Always use diffusion float barrier

○

○

○

3

7 May 2003

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

Tighten firmly to seal

May 2003

○

C

Normal Use

For set-up and first use see E – 1 to E – 9

C–2

Check, connect & set air supply

1

Push together

Pull back to release

Click!

Air ○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

2

Air Set to 100 kPa - 15 psi

3

At least 1000 kpa (150 psi) in high pressure Air supply cylinder

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

May 2003 8

Normal Use

Connection & flushing of water manifold

1

Push to seal onto reservoir

Part #: ZP1FIT/SW/B-QM2-B-200ZN

2

Connect to water manifold

Reservoir support posts

3

Air line from control box

Open outflow control

4

Open to vent bubbles

Manifold venting pinch clamp

9

May 2003

C C–3

C C–4

Normal Use

Check flow values of each hydraulic resistor

1

Flow ml/min

1

Standard resistor shown: flow is colour coded

Tube Colour

Screw Colour

0.01

Black

White

R01HRE/ST/1(2)

0.02

Black

Black

R01HRE/ST/2(2)

0.04

Red

Red

R01HRE/ST/4(2)

0.08

Red

White

R01HRE/ST/8(2)

0.15

Red

Black

R01HRE/ST/15(2)

0.3

Green

White

R01HRE/ST/30(2)

0.45

Green

Red

R01HRE/ST/45(2)

0.6

Green

Black

R01HRE/ST/60(2)

Alternative: Compact hydraulic resistor

Part #

Water flow on case

2

The flow value is...

• Correct, go to

C–5

• Changed, go to

E–5 or 6 May 2003

10

Normal Use

C

Turn on water perfusion to fill each transducer

1

Open pinch valve or clamp

2

Fill transducers

2

Fill transducers

Prefered position for 3 way stopcock - other than PVB DPT-6100 Note: PVB DPT-6100 Transducer shown

11 May 2003

Note: Abbott Transpac 42582-10 Transducer Shown

C–5

C

Normal Use

C–6

Transducer calibration (if required)

1

Turn perfusion off - (C – 5)

2

Set tranducer gain by applying standard external pressure

Shows AP1CMA/TR/2

Connect to transducers Note: Shows Dentsleeve calibration manifold; made according to channel numbers and spacings Part #’s AP1CMA/TR/1to5

Pressurise with syringe

C–7

Connect catheter to transducers

1

Select correct channel

2

Twist & push on firmly

Note: Catheter detail is for Dentsleeve product

May 2003

12

Normal Use

C

Water injection procedure - each channel

1

H2O - no bubbles

3

Inject 5ml of H2O

13 May 2003

2

Open side-port

C–8

C C–8

Normal Use

Water injection procedure - each channel (cont)

4

Close side-port then remove syringe

Note: Arrangement for PVB DPT-6100 transducer shown

May 2003 14

C

Normal Use

Check flow value for air perfusion manometry

1

C–9

Identify air perfusion channel

Red Band

! Only use air perfusion for detection of swallowing in pharynx

2

Ensure resistor for air perfusion channel is correct

!

Air flow rate through hydraulic resistor is x100 water flow rate.

Water flow ml/min

Part #

0.02

Black

Black

R01HRE/ST/2(2)

0.04

Red

Red

R01HRE/ST/4(2)

0.08

Red

White

R01HRE/ST/8(2)

Suitable compact resistors give airflow on case

! Must be installed between manifold and transducer to limit air flow into catheter to less than 10ml/min

15

May 2003

Air flow ml/min

Water Flow ml/min

Part #

2

0.02

R01HRE/CO/2

4

0.04

R01HRE/CO/4

8

0.0

R01HRE/CO/8 8

C

Normal Use

C – 10

Observation & refilling of perfusate reservoir

If perfusate exhausted, large volumes of gas may be perfused down catheter

1

Refill when at 2cm

2

Release pressure

Pull Back

3

Refill

Particle free, degassed, distilled H 20

4

Restart perfusion

Tighten

Repressurise

May 200316

Normal Use

C

Maintain correct perfusate reservoir pressure

C – 11

Monitor air pressure. Maintain at 100kPa/15psi.

1

150

100 15

20 25

10 50

0

2

200

30 35

5 psi kPa

250

Check if air pressure drops

3

Check that air supply is adequate

300 200

400 40 60 20

100

500 80

0

psi kPa

600

OR At least 130 kPa/ 20psi

At least 1000 kPa/ 150psi

17 May 2003

C C – 12

Normal Use

Prevention, recognition and correction of hydraulic resistor blockage

1

Prevention of blockages - Always use perfusate filter

2

Minimise perfusate particle load

Double-distilled or de-ionised water

No particles in reservoir (E-2) Perfusate filter Part # AP1FIL/WA/1

3

4

Replace water perfusate filter regularly - (G-1)

Check perfusate flow rates - assemble 1ml syringe barrel on transducer

1ml syringe

5

Start perfusion - (C-5)

6

Measure time to deliver water

Female/Female adapter Part # ZP1FIT/VP/FTLLC-9

Transducer on rack

Note: for resistor flow rates < 0.15ml/min use 0.25 - 0.50 ml syringe barrels

May 2003

18

C

Normal Use

Prevention, recognition & correction of hydraulic resistor blockage (cont.)

7

Flushing of blocked resistors - remove resistor from circuit

Transducer end

8

Backflush forcibly

9

Observe water flow

OR 11

Remove resistor from circuit

12

Insert flush support tool - (E – 6)

13 Same steps as C – 12.7 to 12.10 above

19 May 2003

10

Re-install - (E – 5)

C – 12

C

Normal Use

C – 13

Compressor

1

Always earth

2

Turn on power switch. Power is on when switch is illuminated

3

Connect compressor air outlet to pump control box

4

Plug in compressor to pump control

5

Press compressor on/off switch. Functioning normally when switch is illuminated

May 2003 20