DePuy Synthes

SYNTHES Small Electric Drive System Instructions for Use

56 Pages

Preview

Page 1

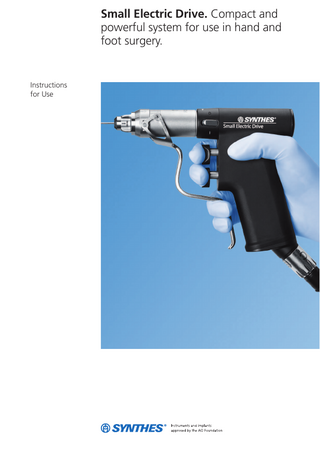

Small Electric Drive. Compact and powerful system for use in hand and foot surgery.

Instructions for Use

Contents

Introduction

General Information

3

Consoles

General Description

6

Set-up

8

Small Electric Drive

General Description

10

Attachments

General Information

12

Drill Attachments

14

Screw Attachments

15

Ream Attachments

16

Other Rotating Attachments

18

Saw Attachments

23

Other Attachments

27

General Information

28

Preparation Prior to Cleaning

29

Manual Cleaning Instruction

30

Mechanical/Automated Cleaning Instruction with Manual Pre-cleaning

32

Lubrication

35

Function Control

37

Care and Maintenance

Small Electric Drive

Instructions for Use

Synthes

1

Contents

Care and Maintenance (continued)

Packaging, Sterilization and Storage

38

Repairs and Technical Service

40

Disposal

41

Troubleshooting

42

System Specifications

43

Electromagnetic Compatibility

Accompanying Documents

Ordering Information

51

Warning This description alone does not provide sufficient background for the direct use of the product. Instruction by a surgeon experienced in handling this product is highly recommended.

2

Synthes

Small Electric Drive

47

Instructions for Use

Introduction General Information

Intended use The Small Electric Drive is designed for use in general traumatology, especially hand and foot applications involving surgical procedures such as drilling, burring, reaming, pin and wire placement, cutting of bone and hard tissue. Safety instructions The Small Electric Drive is only to be used for patient treatment after careful consultation of the instructions for use. It is recommended that an alternative system is available to use during application, as technical problems can never be completely ruled out. The Small Electric Drive is designed for use by physicians and trained medical personnel. DO NOT use any component if damage is apparent. DO NOT use any component if the packaging is damaged. DO NOT use this equipment in the presence of oxygen, nitrous oxide or a mixture consisting of flammable anesthetics and air. To ensure the proper operation of the tool, only use Synthes original accessories. Before the first and every subsequent use, power tools and their accessories/attachments have to run through the complete reprocessing procedure. Protective covers and foils must be fully removed before sterilization. For the tool to function properly, Synthes recommends cleaning and servicing it after each use in accordance with the process recommended in the chapter “Care and Maintenance”. Compliance with these specifications can considerably extend the service life of the tool. Only use Synthes oil (519.970) to lubricate the tool.

Efficiently working cutting tools are the basis for successful surgery. Therefore, it is mandatory to check used cutting tools after every use for wear and/or damage and to replace them if necessary. We recommend using new Synthes cutting tools for every surgery. Cutting tools must be cooled with irrigation liquid to prevent heat necrosis. The user of the product is responsible for proper use of the equipment during surgery. If the Small Electric Drive is used in conjunction with an implant system, make sure to consult the corresponding “Technique Guide”. For important information regarding electromagnetic compatibility (EMC), please refer to the chapter “Electromagnetic Compatibility” in this manual. The tool is classified as type B against electrical shock and leakage current. The tool is suitable for use on patients in accordance with IEC 60601-1. To ensure the proper operation of the tool, Synthes recommends annual maintenance by a Synthes service center. The manufacturer shall assume no responsibility for damage resulting from improper operation, neglected or unauthorized maintenance of the tool.

Precautions: – To avoid injuries, the locking mechanism of the tool has to be activated before every manipulation and before placing the tool back down, i.e. the adjustment sleeve has to be in the LOCK position . – Should the machine drop on the floor and have visible defects, do not use it anymore and send it to the Synthes service center.

Small Electric Drive

Instructions for Use

Synthes

3

Introduction General Information

Accessories/scope of delivery The main components of the Small Electric Drive (SED) are the handpiece, console and electric cables as well as attachments and accessories. An overview of all the components belonging to the Small Electric Drive can be found in the chapter “Ordering Information”. For the system to operate properly, only Synthes cutting tools should be used. Special auxiliaries such as cleaning brushes and Synthes oil are available for cleaning and servicing the system. No oils from other manufacturers must be used. Only Synthes oil (519.970) must be used. Lubricants with other compositions can cause jamming, can have a toxic effect or can have a negative impact on the sterilization results. Only lubricate the power tool and the attachments when clean. Synthes recommends the use of the specifically designed Synthes Vario Cases (68.001.252 and 68.001.253) and of the specifically designed Synthes Washing Basket (68.001.630) to sterilize and store the system. The following components are essential to ensure proper operation: – Small Electric Drive (05.001.175) – Console (05.001.000, 05.001.002 or 05.001.006) – At least one attachment of the system Please refer to the end of these Instructions for Use for an overview of the components of the system. Storage and transport Please use the original packaging for dispatch and transport. If this is no longer available, please contact the Synthes office.

4

Synthes

Small Electric Drive

Instructions for Use

Warranty The warranty for the tools and accessories does not cover damage of any kind resulting from improper use, damaged seals or improper storage and transport. The manufacturer does not accept liability for damage resulting from repairs or maintenance carried out by unauthorized sites.

Explanation of the general symbols used Caution Read the provided Instructions for Use before operating the device. Consult the Instructions for Use before operating the device. The device is classified as type B against electrical shock and leakage current. The device is suitable for use on patients according to the standards defined by CSA 601.1, IEC 60601-1 and UL 60601. Do not immerse device in liquids.

The marked device shall only be used within a specified temperature range.

10PB

With regard to electrical shock, fire, mechanical hazards, only in accordance with UL 60601-1 and CAN/CSA C22.2 No. 601.1 The device meets the requirements of directive 93/42/EEC for medical devices. It is authorized by an independent notified body for which it bears the CE symbol.

2

Do not reuse Products intended for single use must not be reused. Reuse or reprocessing (e.g. cleaning and resterilization) may compromise the structural integrity of the device and/or lead to device failure, which may result in patient injury, illness or death. Furthermore, reuse or reprocessing of single use devices may create a risk of contamination e.g. due to the transmission of infectious material from one patient to another. This could result in the injury or death of the patient or user. Synthes does not recommend reprocessing contaminated products. Any Synthes product that has been contaminated by blood, tissue and/or bodily fluids/matter should never be used again and should be handled according to hospital protocol. Even though they may appear undamaged, the products may have small defects and internal stress patterns that may cause material fatigue.

The European directive 2002/96/EC on waste electrical and electronic equipment (WEEE) applies to this device. This device contains materials that should be disposed of in accordance with environment protection requirements. Please observe national and local regulations. See section entitled Disposal on page 41.

Small Electric Drive

Instructions for Use

Synthes

5

Consoles General Description

The Small Electric Drive (05.001.175) can be supplied with the Standard Console or as an alternative with the Basic Console (without torque limiting function and irrigation). The Standard Console can alternatively be ordered without the torque limiting function.

1

2

6

7

1

2

6

7

3

4

Standard Console with irrigation (05.001.000) 1 Slide control for adjusting the maximum speed for 1 2 Slide control for adjusting the maximum speed for 2 3 Selection switch for torque limiting 4 Selection switch for irrigation 5 Connection for Adapter for Colibri 6 Connection for Electric Pen Drive and Small Electric Drive 1 7 Connection for Electric Pen Drive and Small Electric Drive 2 8 Connection for Foot Switch 9 Twist lock for irrigation pump 10 Adjustment knob for irrigation flow rate 5

Standard Console with irrigation, without torque limiting (05.001.006) 1 Slide control for adjusting the maximum speed for 1 2 Slide control for adjusting the maximum speed for 2 4 Selection switch for irrigation 5 Connection for Adapter for Colibri 6 Connection for Electric Pen Drive and Small Electric Drive 1 7 Connection for Electric Pen Drive and Small Electric Drive 2 8 Connection for Foot Switch 9 Twist lock for irrigation pump 10 Adjustment knob for irrigation flow rate 11 LED Irrigation Ready (Activation with Foot Switch)

For more detailed information about the irrigation, please refer to the Electric Pen Drive Instructions for Use (036.000.800).

6

Synthes

Small Electric Drive

Instructions for Use

5

8

9

11

8

10

4

9

10

Basic Console (05.001.002) 1 Slide control for adjusting the maximum speed for 5 Connection for Adaptor for Colibri 6 Connection for Electric Pen Drive and Small Electric Drive 8 Connection for Foot Switch

1

Notes: – The Slide controls for maximum speed adjustment, the torque limiting and irrigation functions can only be used with the Electric Pen Drive. – When returning the console for repair or maintenance, always return the power cord. – Only the consoles having an SED symbol below the connection can be used with the Small Electric Drive. Other consoles can be sent back to the local Synthes service center for an update. Please contact your local representative for further information.

5

6

8

Color Coding Set (60038602) A color coding set is supplied with every console. Each set contains 3 text stickers, 8 silicone rings in 3 colors (red, blue and white) and 8 stickers of the colored rings. The stickers and silicone rings can be used to indicate on the console and the cables as to how the system has to be assembled.

Note: The silicone rings fixed to the cables have to be removed (moved backwards on the cable) before being washed and fixed again before sterilization.

Content of Set No. 60038602

Small Electric Drive

Instructions for Use

Synthes

7

Consoles

Set-up

Before the initial operation of the device, make sure that the power switch 12 is set to position 0 (OFF). Only connect the console to the power supply with the cable provided via the power plug socket 13 and set the power switch to position 1 (ON). The LED marked with on the front of the console signals the proper operation of the console. If the LED flashes, the console must be sent in for maintenance. A potential equalization connector 14 for an equipotential earth plug is integrated in the console. Existing equipotential earth plugs can be connected there. To increase patient safety, the use is recommended; but according to IEC 60601-1 3rd, it is not mandatory.

8

Synthes

Small Electric Drive

Instructions for Use

14 12 13

Mounting cables on the consoles To mount the respective cables on the consoles, position the nose on the plugs flush with the groove on the plug sockets and insert the plugs. For improved orientation, red dots are provided on the plug and socket that must face upward when connecting the cable. Removing cables To remove the plug, grasp the release sleeve, pull back and remove. The connections 5 – 8 (page 6) are used to connect the following devices: (5): Connection for a Colibri handpiece (6 and 7): Connections for an Electric Pen Drive or a Small Electric Drive (8): Connection for the Foot Switch

Connections that are not in use can be sealed off with the protective caps provided.

Precautions: – Do not place consoles directly against a wall, as the console’s ventilation will be impaired. Maintain a distance of at least 3 cm. – Only place consoles on smooth surfaces. – Do not lay textiles or objects under the console. These can be sucked up and block the ventilation inlet. – Do not hang irrigation liquid directly above the console in order to prevent liquid from dripping onto the console. – Do not pull on the cable! Always activate the release sleeve. – The use of HF (high frequency) equipment for tissue coagulation can cause electromagnetic disturbances – in this case, the cables should be separated as far as possible.

Small Electric Drive

Instructions for Use

Synthes

9

Small Electric Drive General Description

1 Trigger for speed regulation 2 Trigger for switching to reverse/oscillating drilling 3 Attachment coupling 4 Release buttons for attachment 5 Adjustment sleeve 6 Lock slide 7 Cable IN/OUT 8 LOCK 9 ON 10 OSC DRILL

3 4

2

1

Protective systems The Small Electric Drive System is equipped with a thermal overload safety system that shuts off the tool if it becomes too hot during use. After it cools, the tool can be used again. Mounting cable on handpiece Move the adjustment sleeve (5) on the handpiece into the position Cable IN/OUT (7) by pushing the lock slide (6) in the direction indicated by the arrow and by simultaneously turning the adjustment sleeve (5) to the desired position. To insert the plug, you can either align the groove on the plug with the notch in the sleeve or align the symbol present both on the sleeve and on the plug (Fig. 2). Once the plug is inserted, push the lock slide (6) in the direction indicated by the arrow and rotate the adjustment sleeve simultaneously into the LOCK position (8). The cable is now firmly locked in the handpiece and the handpiece is in locked mode.

Figure 2

10

Synthes

Small Electric Drive

Instructions for Use

5

Figure 1

6

7

9

10

8

To remove, push the lock slide (6) in the direction indicated by the arrow, rotate the adjustment sleeve (5) into the Cable IN/OUT position (7) and remove the cable.

Speed and rotational direction control Adjustment sleeve in the ON position By turning the adjustment sleeve into the ON position (9), the handpiece can be set to a clockwise running direction. When pressing on the bottom trigger, the tool starts running in this clockwise direction. When the bottom and top triggers are pressed at the same time, the tool immediately switches to reverse motion. When the bottom trigger is released, the tool immediately stops. Adjustment sleeve in the OSC DRILL position ( ) When the bottom and top triggers are pressed at the same time, the tool immediately switches to oscillating rotation. When the top trigger is released, the tool returns to normal forward rotation. In addition to locking the cable, the LOCK position (8) is also used for a safety switch-off when changing attachments and tools and before laying it down. This prevents the accidental start-up of the unit while performing these activities. For instructions on mounting the attachments, see page 12.

Important: – Never place the Small Electric Drive on a magnetic surface since the machine might start unintentionally. – Always check its functioning before use. – Pay particular attention to all the instructions in the individual sections that are identified with “Precaution”. – Components that are no longer useful must be disposed of in accordance with the local and national regulations. – Always have a back-up system to avoid problems due to a faulty system. – Always wear personal protective equipment (PPE) including safety goggles when working with the Small Electric Drive system.

Small Electric Drive

Instructions for Use

Synthes

11

Attachments General Information

The Small Electric Drive System offers a broad range of attachments. A wide range of rotating attachments has color-coded rings, so that they can easily be identified. The table on the next page lists the different types of attachments available, the color coding as well as the speed of each attachment.

Mounting the attachments Insert the attachment into the attachment coupling (Fig. 1). If the positioning pins do not lock into place right away, twist the attachment a bit to the right or left until it locks into the correct position. Check if the attachment is seated correctly by gently pulling on it. Removing the attachments Press the attachment release buttons (4, see Fig. 1 on page 10) simultaneously and remove the attachment from the coupling.

Precautions: – To prevent injury, the power tool must be switched off with the safety system (see page 11) during each manipulation. – Only use original attachments and tools from Synthes. Damage that arises from using attachments and tools made by other manufacturers is not covered by the warranty. – Never use an attachment in reverse mode with an old flexible shaft as this could cause serious injury to the patient. For this application, we recommend to use exclusively the attachment without possible reverse motion (05.001.255).

12

Synthes

Small Electric Drive

Instructions for Use

Figure 1

Article Number

Speed

Color coding

05.001.250 AO/ASIF Quick Coupling

1120 rpm

Blue

05.001.252 Chuck (Drilling Speed), with Key, clamping range up to ⭋ 4.0 mm

1120 rpm

Blue

05.001.253 Chuck (Drilling Speed), with Key, clamping range up to ⭋ 7.3 mm

1120 rpm

Blue

Screw Attachments

05.001.251 Screw Attachment with AO/ASIF Quick Coupling

285 rpm

Red

Ream Attachments

532.017

AO/ASIF Quick Coupling for Medullary Reaming

285 rpm

Red

532.018

Hudson Quick Coupling for Medullary Reaming

285 rpm

Red

532.019

Trinkle Quick Coupling for Medullary Reaming

285 rpm

Red

532.020

Trinkle Quick Coupling, modified, for Medullary Reaming

285 rpm

Red

532.015

Drill Attachments

Other Rotating Attachments

Saw Attachments

Other Attachments

Product

Quick Coupling for DHS/DCS triple reamers

285 rpm

Red

05.001.254 Chuck (Reaming Speed), with Key, clamping range up to ⭋ 7.3 mm, with reverse motion

285 rpm

Red

05.001.255 Chuck (Reaming Speed), with Key, clamping range up to ⭋ 7.3 mm, without reverse motion

285 rpm

Red

532.011

Mini Quick Coupling

3050 rpm

None

532.012

J-Latch Coupling

3050 rpm

None

770 rpm

None

05.001.187 Burr Attachment

15000 rpm

None

511.300

Radiolucent Drive

3050 rpm

None

532.021

Oscillating Saw Attachment

15000 rpm

None

532.023

Oscillating Saw Attachment II (Crescentic Technique)

15000 rpm

None

532.026

Large Oscillating Saw Attachment

15000 rpm

None

511.773

Torque Limiter, 1.5 Nm, for AO/ASIF Quick Coupling

–

None

511.776

Torque Limiter, 0.8 Nm, with AO/ASIF Quick Coupling

–

None

511.777

Torque Limiter, 0.4 Nm, with AO/ASIF Quick Coupling

–

None

05.001.186 Quick Coupling for Kirschner Wires

Technical data is subject to tolerances. Specifications are approximate and may vary from one device to another or as a result of power supply fluctuations.

Small Electric Drive

Instructions for Use

Synthes

13

Attachments

Drill Attachments

AO/ASIF Quick Coupling (05.001.250) For tools with an AO/ASIF coupling shaft. Mounting and removing the tools Insert the tool into the attachment from the front applying slight pressure and turning slightly. It is not necessary to operate the coupling sleeve of the attachment. To disconnect, push the coupling sleeve of the attachment back and remove the tool.

Chucks There are two Drill Attachments Chucks available as Drill Attachments for the Small Electric Drive system. Article number

Clamping range

Spare key

Comments

05.001.252

0 – 4.0 mm

310.932

For drilling

05.001.253

0 – 7.3 mm

510.191

For drilling

Inserting cutting tools Open the jaws of the chuck using the appropriate key or by hand. Insert the shaft of the tool into the open drill chuck and close it by twisting the chuck. Make sure that the shaft lies central to the three jaws. Tighten the drill chuck with the key. Make sure that the teeth of the key engage correctly in the toothed rim of the chuck. Removing cutting tools Open the chuck with the key and remove the tool.

Precautions: – Do not use the Small Electric Drive for acetabular reaming. – Check the cutting tool for wear and/or damage after each use and replace if necessary. – To ensure good fixation of the tools, make sure the toothed rims on the drill chuck and key are not worn.

14

Synthes

Small Electric Drive

Instructions for Use

Attachments

Screw Attachments

Screw Attachment, with AO/ASIF Quick Coupling (05.001.251) Mounting and removing the tools Insert the tool into the attachment from the front by applying slight pressure and turning slightly. It is not necessary to operate the coupling sleeve of the attachment. To disconnect, push the coupling sleeve of the attachment back and remove the tool.

Precautions: – Care should be taken when inserting screws with the drive unit. – Never fully insert screws with the drive unit. The last turns or locking should always be done manually. – Always use an appropriate torque limiting attachment when putting locking screws into a locking plate. – Theoretically, it is also possible to use the AO/ASIF Quick Coupling (05.001.250) to insert screws. However, the Screw Attachment (05.001.251) has a lower speed and a higher torque and is therefore more suitable. Screws with a large diameter may not be able to be inserted with the AO/ASIF Quick Coupling as the torque may not suffice. – The attachment is also suitable for application at a lower rpm and/or higher torque.

Small Electric Drive

Instructions for Use

Synthes

15

Attachments

Ream Attachments

Quick Couplings for Medullary Reaming AO/ASIF Quick Coupling (532.017) Hudson Quick Coupling (532.018) Trinkle Quick Coupling (532.019) Trinkle Quick Coupling, modified (532.020) The Quick Couplings for Medullary Reaming enable the use of flexible shafts with the appropriate coupling geometry. Reverse motion, which can damage the flexible shafts, is prevented by a special mechanical system. Inserting cutting tools into the coupling Maneuver the unlocking ring on the attachment backward and insert the tool (such as a drill bit) while rotating it slightly until it locks into place. Release the ring. Check if the tool is seated correctly in the coupling by gently pulling on it. Removing cutting tools Push the unlocking ring on the attachment backward and remove the tool.

Precautions: – Do not use “Quick Couplings for Medullary Reaming” for acetabular reaming. They may only be used for medullary reaming. – Check the cutting tool for wear and/or damage after each use and replace if necessary.

Quick Coupling for DHS/DCS Triple Reamers (532.015) For DHS/DCS Triple Reamers; can also be used to open the medullary cavity with most of the Synthes nailing systems. Mounting and removing the tools To connect the tool, push the coupling sleeve forward and then introduce the tool while turning slightly. To disconnect, push the coupling sleeve of the attachment forward and remove the tool.

16

Synthes

Small Electric Drive

Instructions for Use

Chucks There are two chucks available as Ream Attachments for the Small Electric Drive system. Article number

Clamping range

Spare key

Comments

05.001.254

0 – 7.3 mm

510.191

For drilling and medullary reaming, with reverse motion

05.001.255

0 – 7.3 mm

510.191

For drilling and medullary reaming, without reverse motion

Inserting cutting tools Open the jaws of the chuck using the appropriate key or by hand. Insert the shaft of the tool into the open drill chuck and close it by twisting the chuck. Make sure that the shaft lies central to the three jaws. Tighten the drill chuck with the key. Make sure that the teeth of the key engage correctly in the toothed rim of the chuck. Removing cutting tools Open the chuck with the key and remove the tool.

Precautions: – Do not use the Small Electric Drive for acetabular reaming. – Check the cutting tool for wear and/or damage after each use and replace if necessary. – To ensure good fixation of the tools, make sure the toothed rims on the drill chuck and key are not worn. – Use the Chuck with Reverse motion (05.001.254) only with tools that are approved for such use. Otherwise, the tool may break with subsequent damage.

Small Electric Drive

Instructions for Use

Synthes

17

Attachments

Other Rotating Attachments

Mini Quick Coupling (532.011) J-Latch Coupling (532.012) For tools with a Mini Quick or J-Latch coupling shaft. Mounting and removing the tools To connect the tool, pull the coupling sleeve back and then introduce the tool while rotating slightly. To disconnect, push the coupling sleeve of the attachment back and remove the tool.

Quick Coupling for Kirschner Wires (05.001.186) Kirschner Wires of any length with a diameter of 0.6 – 3.2 mm can be used with the Quick Coupling for Kirschner Wires. 1. Adjust the Kirschner Wire diameter according to the label on the adjusting sleeve K. Slightly press the adjusting sleeve axially against the handpiece and rotate the sleeve. 2. Apply a slight amount of pressure to insert the Kirschner Wire from the front or back into the cannulation J. The wire is held automatically. 3. Adjust the working length by pulling on the wire. 4. To affix the wire, pull the tension lever L against the tool with your little finger and ring finger. Only pull the tension lever against the tool as much as necessary. The clamping force can be varied by pulling and releasing the clamping lever. 5. Insert the wire into the bone. Apply the clamping force as long as the wire is advanced. 6. To adjust the grip on the wire, reduce the clamping force and move the tool to the desired length. Reclamp the wire by pulling on the tension lever.

18

Synthes

Small Electric Drive

Instructions for Use

J

K

L

Radiolucent Drive (511.300) The Radiolucent Drive can be used with the Small Electric Drive in combination with the AO/ASIF Quick Coupling (05.001.250) and the Adapter for the Radiolucent Drive (532.031). Coupling the Radiolucent Drive to the power tool Connect the AO/ASIF Quick Coupling to the Small Electric Drive and the adapter to the Quick Coupling. Position the Radiolucent Drive as far as it will go over the Quick Coupling and the adapter and rotate it into the desired working position. Support the drive with your free hand.

(05.001.250)

(532.031)

(511.300)

Inserting the drill bit Pull the ring on the attachment forward and position the drill bit inside the coupling as far as it can go while rotating it slightly. Engage the ring on the attachment back in order to fix the drill. Check if the drill bit is seated correctly by gently pulling on it. Removing the drill bit Follow the same procedure in reverse order.

Small Electric Drive

Instructions for Use

Synthes

19