Operation Manual

2 Pages

Preview

Page 1

Surgical Handpiece

SGS / SGA OM-SH0015E 004

Intended to Use This handpiece is designed for surgical use by qualified personnel.

CAUTION • When operating the handpiece always consider the safety of the patient. • Do not disassemble or alter the handpiece. For service or repair, contact authorized dealer. • Check for vibration, noise and overheating before use. If any abnormalities are found, stop using the handpiece immediately and contact authorized dealer. • Should the handpiece function abnormally, cease operation immediately and return the handpiece to an authorized dealer for repair. • Do not allow any impact on to the sheath. Do not drop the handpiece. • Ball bearings are articles of consumption. When you leave it broken, it may cause burn injury. • Do not turn the Bur Lock Ring while the handpiece is rotating. • Do not connect or disconnect the handpiece until the motor has completely stopped. • Ensure the bur and motor connection. Improper connection may cause spin the bur out. • Immediately after use, the handpiece should be cleaned, lubricated and sterilized before blood, etc. dries inside the handpiece. If blood is left on the handpiece, it can become clotted and causing rust. • Do not wipe nor immerse the handpiece in acidic water or acidic solutions. • Perform periodical maintenance checks. • If the handpiece has not been used for a long period, check for noise, vibration, and overheating before use.

1. Specifications Model Handpiece Type Gear Ratio Allowable Max. Speed Bur Size Model Handpiece Type Gear Ratio Allowable Max. Speed Bur Size Model Handpiece Type Gear Ratio Allowable Max. Speed Bur Size Model Handpiece Type Gear Ratio Allowable Max. Speed Bur Size

SGA-ES Angle / Short

Short Surgical Burs ø2.35 x L70 mm SGA-E2S Angle / Short

Short Surgical Burs ø2.35 x L70 mm SGS-ES Straight / Short

Short Surgical Burs ø2.35 x L70 mm SGS-E2S Straight / Short

Short Surgical Burs ø2.35 x L70 mm

SGA-EM Angle / Medium 1:1 Direct Drive 40,000 min-1(rpm) Medium Surgical Burs ø2.35 x L95 mm SGA-E2M Angle / Medium 1:2 Increasing 80,000 min-1(rpm) Medium Surgical Burs ø2.35 x L95 mm SGS-EM Straight / Medium 1:1 Direct Drive 40,000 min-1(rpm) Medium Surgical Burs ø2.35 x L95 mm SGS-E2M Straight / Medium 1:2 Increasing 80,000 min-1(rpm) Medium Surgical Burs ø2.35 x L95 mm

SGA-EL Angle / Long

Long Surgical Burs ø2.35 x L125 mm SGA-E2L Angle / Long

Long Surgical Burs ø2.35 x L125 mm SGS-EL Straight / Long

Long Surgical Burs ø2.35 x L125 mm SGS-E2L Straight / Long

Long Surgical Burs ø2.35 x L125 mm

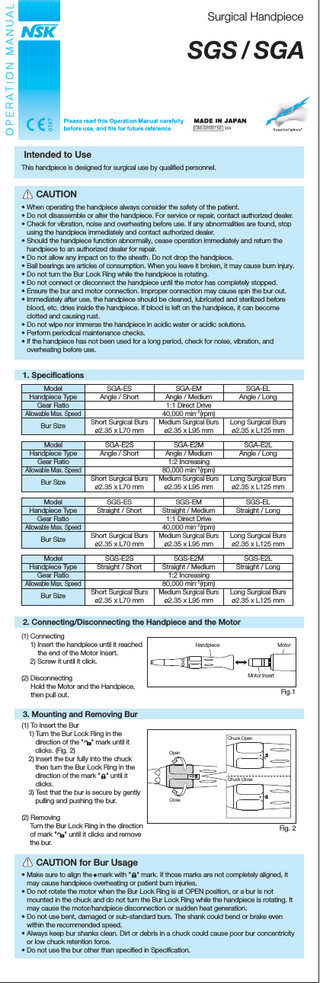

2. Connecting/Disconnecting the Handpiece and the Motor (1) Connecting 1) Insert the handpiece until it reached the end of the Motor Insert. 2) Screw it until it click.

Handpiece

Motor

Motor Insert

(2) Disconnecting Hold the Motor and the Handpiece, then pull out.

Fig.1

3. Mounting and Removing Bur (1) To Insert the Bur 1) Turn the Bur Lock Ring in the direction of the " " mark until it clicks. (Fig. 2) 2) Insert the bur fully into the chuck then turn the Bur Lock Ring in the direction of the mark " " until it clicks. 3) Test that the bur is secure by gently pulling and pushing the bur. (2) Removing Turn the Bur Lock Ring in the direction of mark " " until it clicks and remove the bur.

Chuck Open Open

Chuck Close

Close

Fig. 2

CAUTION for Bur Usage • Make sure to align the mark with " " mark. If those marks are not completely aligned, it may cause handpiece overheating or patient burn injuries. • Do not rotate the motor when the Bur Lock Ring is at OPEN position, or a bur is not mounted in the chuck and do not turn the Bur Lock Ring while the handpiece is rotating. It may cause the motor/handpiece disconnection or sudden heat generation. • Do not use bent, damaged or sub-standard burs. The shank could bend or brake even within the recommended speed. • Always keep bur shanks clean. Dirt or debris in a chuck could cause poor bur concentricity or low chuck retention force. • Do not use the bur other than specified in Specification.

4. The Bur Use this handpiece for Implant with straight handpiece bur, mount the Stopper (Option). This may not use for Speed Increase Handpiece. (SGS-EM,SGS-EL,SGS-E2S, SGS-E2M, SGS-E2L, SGA-EM, SGA-EL, SGA-E2S, SGA-E2M, SGA-E2L) Stopper: Order No. Y900 160 Thread Portion

Screwdriver

Stopper (Option)

Fig. 3 Mount the Stopper (SGS-ES,SGA-ES) 1) Open the chuck to turn the Bur Lock Ring. (Fig.2) 2) Insert the Stopper from threaded portion in to the chuck and screws it in with provided screwdriver.

5. Before Using The Handpiece Follow the check below, before use. If any abnormalities are found, stop using the handpiece immediately and contact dealer. 1) Mount the Bur. (Do not exceed maximum rotation speed for the Bur) 2) Check that there is no abnormal rotation, vibration, noise and overheating. If you found any of them, do not use the handpiece and return it to the dealer for repair. 3) If there are no immediate apparent abnormalities, continue to rotate the handpiece for about 1 minute. Then check that there is no abnormal heating on the outer surface. 4) Operate it if there are not abnormalities above.

6. Irrigation Nozzle Insert the Irrigation Nozzle into the handpiece. And, push the Irrigation Tube into the nozzle until it reaches end.

Irrigation Tube Irrigation Nozzle

Fig. 4 Irrigation Nozzle for SGA-ES, SGA-E2S, SGS-ES, SGS-E2S: Order No. H263 018 for SGA-EM, SGA-E2M, SGS-EM, SGS-E2M: Order No. H263 023 for SGA-EL, SGA-E2L, SGS-EL, SGS-E2L: Order No. H263 024

7. Maintenance

CAUTION After each operation, be sure to keep the handpiece after cleaning, lubrication, and sterilization. If the blood is left on the handpiece, it can be clotted causing rusty. (1) Cleaning Clean the Irrigation Nozzle inside with clean water. This handpiece can be washed via Thermo Disinfector. (2) Lubrication Supply lubricate spray after each use and/or before each autoclaving. PANA-SPRAY Plus / PANA-SPRAY (Fig. 5) 1) Push E-type spray nozzle attachment over the lubricate spray nozzle until it firmly seats. 2) Shake the can 3-4 times to well mix lubricant and propellant. 3) Insert the spray nozzle in the rear of the handpiece and spray the lubricant into the handpiece 2-3 times for 2-3 seconds each time.

E-type Spray Nozzle Handpiece

PANA SPRAY Plus / PANA SPRAY

Fig. 5

CAUTION • Be sure to hold the handpiece firmly to prevent slipping out of hand by the spray pressure when lubricating. • Supply lubricant until it comes out of the handpiece head. • Repeat this lubrication until you see no foreign articles such as blood penetrated into the handpiece comes out. • If the oil dripping from the handpiece head is not clean after the lubrication, internal parts may tear and wear. Contact the dealer for a repair. • Hold the lubricate spray can upright. (3) Sterilization Steam autoclave is recommended. Sterilization is required first time you use and after each patient as noted below. Autoclave Procedure 1) Scrub dirt and debris from the handpicec, and wipe clean with alcohol-immersed cotton swab or cloth. Do not use a wire brush. 2) Lubricate with lubricate spray. Refer to (2) Lubrication. 3) Insert into an autoclave pouch. Seal the pouch. 4) Autoclavable up to max. 135°C. Ex.) Autoclave for 20 min. at 121°C or 15 min. at 132°C. 5) Keep the handpiece in the autoclave pouch to keep it clean until you use it. Sterilization at 121°C for more than 15 minutes is recommended by EN13060 or EN ISO17665-1.

The EU directive 93/42/EEC was applied in the design and production of this medical device.

2013.12.20 01 M