Alger

ALGERBRUSH II Directions for Use

Directions for Use

2 Pages

Preview

Page 1

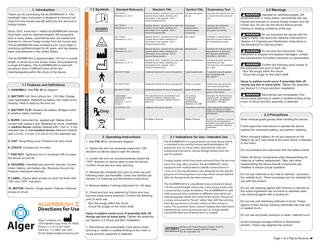

1.2 Symbols

1. Introduction

Standard Reference

Standard Title

Symbol Title

Explanatory Text

ISO 15223-1 Reference no. 5.4.3

Medical devices - Symbols to be used with Consult instructions medical device labels, labelling and for use information to be supplied - Part 1: General Requirements.

Indicates the need for the user to consult the instructions for use.

ISO 15223-1 Reference no. 5.1.2

Medical devices - Symbols to be used with medical device labels, labelling and information to be supplied - Part 1: General Requirements.

Indicates the authorized representative in the European Community.

ISO 15223-1 Reference no. 5.2.7

Medical devices - Symbols to be used with Non-sterile medical device labels, labelling and information to be supplied - Part 1: General Requirements.

Indicates a medical device that has not been subjected to a sterilization process.

ISO 15223-1 Reference no. 5.1.1

Medical devices - Symbols to be used with Manufacturer medical device labels, labelling and information to be supplied - Part 1: General Requirements.

Indicates the medical device manufacturer as defined in EU Directive 90/385/EEC, 93/42/EEC, 98/79/EC

ISO 15223-1 Reference no. 5.1.3

Medical devices - Symbols to be used with Date of Manufacture medical device labels, labelling and information to be supplied - Part 1: General Requirements.

Indicates the date when the medical device was manufactured. Accompanied by a date.

IEC 60417-5840

Graphical Symbols for Use on Equipment

Type B applied part

To identify a type B applied part complying with IEC 60601-1

IEC 60417-5007

Graphical Symbols for Use on Equipment

Power-on symbol

1. ASSEMBLY: See FIG. III for diagram.

Switch that puts equipment into a fully powered state

IEC 60417-5008

Graphical Symbols for Use on Equipment

Power-off symbol

Switch that will disconnect power to the device

2. BATTERY: AA. Non-Lithium Ion. 1.5V Max Charge. User replaceable. Retained by battery clip inside of the housing. Held in place by the end nut.

765/2008/EC 768/2008/EC MDD 93/42/EEC Articles 4,11,12,17 Annex II

The requirements for accreditation and market surveillance relating to the marketing of products; Medical Device Directive.

CE marking Conformité Européene Notified Body Reference no. ###

Indicates the medical device manufacturer, as defined in EU Directive 90/385/EEC, 93/42/EEC, 98/79/EC

21 CFR 801.109

Labeling; Prescription devices.

Prescription Use Only

USA Federal law restricts this device to sale by or on the order of a licensed healthcare practitioner.

2006/66/EC

EU Battery Directive

Battery Disposal

In the EU, batteries in product should not be disposed as unsorted municipal waste and should instead be disposed separately.

Thank you for purchasing the ALGERBRUSH II. This handheld rotary instrument is designed to remove rust rings from the human eye left behind by the removal of foreign bodies.

The ALGERBRUSH is approximately 120 mm in overall length, is driven by a low torque motor, and powered by a single AA battery. The ALGERBRUSH is sold with accessory burrs of different sizes which are interchangeable within the chuck of the device.

Derived From Standards

Since 1970, more than 1 million ALGERBRUSH devices have been used by ophthalmologists, ER physicians and, in many states, optometrists who are trained and licensed to remove foreign bodies from the human eye. The ALGERBRUSH was invented by Dr. Leon Alger, a practicing ophthalmologist for 40 years, and has always been manufactured in the United States.

EC REP

NON STERILE

3. BATTERY CLIP: Retains the battery. Bridges motor to positive battery terminal. 4. BURR: Instrument tip, applied part. Makes direct contact with patient’s eye. Retained by chuck. Available in medical device carbide material with 1 mm or .5 mm diameter tips or non-medical device diamond material with 2.5 mm, 3.5 mm, 4.0 mm or 5.0 mm diameter tips.

Not Derived From Standards

1.1 Features and Definitions

Only

2. Operating Instructions

5. CAP: Snug fitting cover. Protects burr and chuck.

1. See FIG. III for component diagram.

6. CHUCK: Couples burr to motor.

2. Tighten the end nut clockwise toward the “ON” direction on device label to start the device.

7. END NUT: Tightened (on) or loosened (off) to power the device on and off. 8. HOUSING: Handheld grip point for clinician. Covers motor, battery, and battery clip. Receives the end nut. Protects instrument internals. 9. LABEL: Device label printed on silver foil finish with “ON” and “OFF” indicators. 10. MOTOR: Electric. Single speed. Outputs rotational torque on chuck.

Directions for Use

Alger

Alger Company, Inc. 320 Flightline Lago Vista, TX 78645 Phone: (+1) (512) 267-0383 Toll Free: (+1) (800) 320-1043 Email: [email protected]

3. Loosen the end nut counterclockwise toward the “OFF” direction on device label to stop the device. Confirm chuck and burr stop spinning. 4. Sterilize the nonsterile burr prior to initial use and following each use thereafter. Clean and sterilize per Section 3.4 Cleaning and Sterilization Instructions. 5. Remove battery if storing instrument for >30 days. 6. Chuck and burr are retained by friction and may become loose during shipment. Confirm the following prior to each use: · Burr fits snugly within the chuck · Chuck fits snugly on the motor shaft Injury to patient could occur if assembly falls off during use due to loose parts. Tighten the assembly per Section 3.3 Chuck and Burr Installation. 7. Discontinue use immediately if the device stops spinning or visible or audible binding of the motor or chuck and burr assembly is detected.

Authorized representative in the European Community

2.1 Indications for Use / Intended Use The ALGERBRUSH II is a prescription use only device which is intended to be used by trained ophthalmologists, ER physicians and, in many states, optometrists who are trained and licensed to remove foreign bodies from the eye of a patient. Foreign bodies which have been removed from the eye may leave rust rings after removal. The ALGERBRUSH, when equipped with medical device carbide material burrs in 1 mm or .5 mm tip diameters, was designed for the specific purpose of removing these rust rings which remain behind after the foreign body has been removed. The ALGERBRUSH II is a handheld rotary instrument about 120 mm overall length which uses a low torque motor and is powered by a single AA battery. The ALGERBRUSH is sold with accessory burrs available in different sizes which are interchangeable within the Chuck of the device. The use of a rotary instrument to "brush" rather than drill the rust ring from the eye leaves a smooth surface on the cornea or sclera. This promotes faster, cleaner healing than alternative treatments for rust ring removal such as, a large needle, manual off label use of dental burrs or scalpel.

Advena Ltd. Tower Business Centre, 2nd Flr., EC REP Tower Street, Swatar, BKR 4013 Malta Tel: 44 1926 800 153

2.2 Warnings WARNING Intended for ophthalmologists, ER physicians and, in many states, optometrists who are trained and licensed to remove foreign bodies from the human eye. Do not use the device without proper training on treating conditions of the eye. WARNING Do not autoclave the device with the battery inside. Use approved cleaning instructions in Section 3.4 Cleaning and Sterilization Instructions in the Directions For Use document. WARNING Do not drop the instrument. If the instrument is dropped and appears damaged, contact the manufacturer for further instruction or replacement. WARNING Confirm the following upon receipt of the instrument and prior to each use: · Burr fits snugly within the chuck · Chuck fits snugly on the motor shaft Injury to patient could occur if assembly falls off during use due to loose parts. Tighten the assembly per Section 3.3 Chuck and Burr Installation. WARNING Discontinue use immediately if the device stops spinning or visible or audible binding of the motor or chuck and burr assembly is detected.

2.3 Precautions Wear medical-grade gloves while handling the device. Follow approved instructions to operate the device, replace the instrument battery, and perform cleaning. When changing battery, do not put pressure on the battery clip as it may break at the point where it attaches to the motor. Do not autoclave the instrument with the battery inside. Retain all device components while disassembling for cleaning or battery replacement. Take care when reassembling the device that all components are installed to ensure proper operation. Do not use chemical or dry heat to sterilize / autoclave the carbide burrs. These processes are not validated for use with the product. Do not use cleaning agents with chlorine or chloride as the active ingredients are corrosive to stainless steel. Use cleaning agents with a neutral pH. Do not use cold sterilizing methods on burrs. These agents contain strong oxidizing chemicals that may dull or weaken burrs. Do not use enzymatic solutions to clean / debride burrs. Avoid prolonged storage of Burrs in disinfectant solution. These may degrade the product.

Page 1 of 2 Flip to Reverse

2.4 Contraindications

3.1 Storage and Handling

No known contraindications. Use at the direction and supervision of a trained medical professional.

Remove battery if storing instrument for more than 30 days. Suggested environmental conditions of use: 15-35°C, 25-90% relative humidity, 70-108 kPa.

3.3 Chuck and Burr Installation

Confirm the following prior to each use: · Burr fits snugly within the chuck · Chuck fits snugly on the motor shaft

2.5 Potential and Known Risks May cause patient harm if operated incorrectly by an untrained user. Do not use this device unless you are a trained medical professional.

Injury to patient could occur if assembly falls off during use due to loose parts. Tighten the assembly per Section 3.3 Chuck and Burr Installation.

Confirm the following prior to each use: · Burr fits snugly within the chuck · Chuck fits snugly on the motor shaft

Carbide burrs can be transported wet or dry. Protect from physical damage. Wet transport increases the chance of staining or corrosion to the Burr.

Injury to patient could occur if assembly falls off during use due to loose parts. Tighten the assembly per Section 3.3 Chuck and Burr Installation.

3.2 Battery Installation 1. See FIG. III for diagram of components.

3. Maintenance Follow these directions to tighten the friction retainer on the chuck and burr assembly if loose.

2. Loosen the end nut counterclockwise toward the “OFF” direction on device label to stop the device.

Loose motor shaft coupling. Place chuck base in small pliers with base slit oriented away from user as shown in FIG. I. Pinch gently. Test fit. Repeat, as necessary. Avoid excess force. Excess force will close the base and prevent motor shaft coupling.

3. Remove chuck and burr assembly per Section 3.3 Chuck and Burr Installation. 4. Remove end nut. 5. Slide motor and battery clip assembly out of housing. 6. Do not to put pressure on the battery clip as it may break at the point where it attaches to the motor.

FIG. I

7. Remove battery.

Loose burr coupling. Place chuck tip in small pliers with chuck tip facing away from user as shown in FIG. II . Pinch gently. Test fit. Repeat, as necessary. Avoid excess force. Excess force will close the tip and prevent burr coupling. FIG. II

8. To clean the chuck and burr assembly, Prepare a pH-neutral cleaning solution. 9. Place the chuck and / or burr in the dedicated instrument block (if applicable) and then place into a sonication unit.

5. To remove chuck and burr assembly, loosen the end nut counterclockwise toward the “OFF” direction on device label to stop the device.

10. Follow the pH-neutral cleaning solution manufacturer’s instructions for correct concentration, exposure time, temperature, and water quality.

6. Grasp base of chuck with fingers and pull away from motor shaft or gently pry chuck off motor shaft with suitable instrument.

11. Completely submerge the chuck and / or burr in the cleaning solution and sonicate for > fifteen (15) minutes.

7. To replace burr, remove chuck and burr assembly from motor shaft per instructions above.

12. Perform a final thorough rinse of the chuck and / or burr and instrument block (if applicable) under running warm tap water for > one (1) minute.

8. Grasp base of chuck with fingers and grasp shaft of burr with Foley hemostat. Pull apart. 9. Grasp base of chuck with fingers and grasp middle of new, sterilized burr shaft with Foley hemostat. Push burr into chuck until snug.

13. Inspect the chuck and / or burr to confirm the removal of debris. If necessary to remove additional debris, brush burr flutes lightly with a nylon bristle brush. 14. Dry the device using a non-shedding wipe or clean compressed air.

9. Re-insert motor and battery clip assembly into housing.

2. Do not autoclave the instrument with the battery inside.

10. Check the following to ensure motor is seated:

3. To clean the entire instrument, remove chuck and burr assembly per Section 3.3 Chuck and Burr Installation. 4. Retain chuck and burr assembly intact if possible to avoid loss of burr. 5. Clean housing with alcohol or disenfectant wipes such as Optim 1.

1

7. Do not use a worn or damaged burr. These units reached end of life and should be replaced.

4. Loosen the end nut counterclockwise toward the “OFF” direction on device label to stop the device until ready for use.

8. Install battery negative (-) pole first against motor.

FIG. III

· Broken tip · Broken flute section · Corrosion or other obvious defects

3. Gently push chuck and burr assembly onto motor shaft until the base of the chuck is close to, but not touching, top of housing.

3.4 Cleaning and Sterilization Instructions

9. Partially tighten end nut.

6. Visually inspect the burr tip for wear and damage before and after cleaning such as:

2. To install chuck and burr assembly, tighten the end nut clockwise toward the “ON” direction on device label to start the device. The device must be “ON” to ensure the motor is seated.

1. See FIG. III for diagram of components.

· Motor shaft centered in hole at tip of housing · Tip of motor shaft even with top of housing

Do not modify this equipment.

1. See FIG. III for diagram of components.

15. Inspect each chuck and / or burr to ensure all debris is removed. 16. Steam sterilize the chuck and / or burr assembly to the parameters shown in FIG. IV. These parameters are validated as capable of preparing carbide or diamond burrs for reuse. Any deivation from these instructions should be properly validated for effectiveness and potential adverse results. 17. Store the carbide or diamond burr in a sterilization pouch or instrument block until required. Burrs are shipped in two configurations: · Single. Store in pouches validated for sterilization. · Pack. Store in dedicated instrument block.

OFF

ON

FIG. IV

5

Only

4

6

2797

7

8

Dispose of device batteries as per local requirements.

10

2

3

7

Pre-vacuum (4 Pulses)

5

134°C (273°F)

10

ALGERBRUSH II Directions For Use (DFU) The Alger Company Rev 06 12AUG2020 AB2INST Printed in the USA

Page 2 of 2 Flip to Front