deSoutter

CSB-100-A Cast Saw System Operating Instructions Ver 1.2

Operating Instructions

20 Pages

Preview

Page 1

Operating Instructions

International English

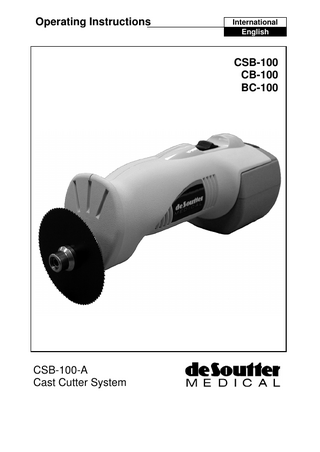

CSB-100 CB-100 BC-100

CSB-100-A Cast Cutter System

DE SOUTTER MEDICAL CSB-100-A CAST CUTTER SYSTEM Index

Page

Section 1: Important Safety Instructions ... 3 Warnings & Safety Rules ... 3 Environmental Conditions For Use ... 4 Recommended Duty Cycle ... 4 Section 2: General Instructions ... 5 Product Description ... 5 Maintenance & Cleaning ... 5 Section 3: System Assembly ... 6 Setting Up the Battery Charger ... 6 Charging the Battery... 6 Battery Disposal ... 7 Battery Care Guidance ... 7 Battery Connection To Cast Cutter... 8 Battery Removal From Cast Cutter... 8 Cast Cutter Controls ... 8 Fitting Of Saw Blade ... 9 Removal Of Saw Blade ... 9 Cutting Technique ... 9 Section 4: Technical Information ... 10 Part Number Details ... 10 Optional accessories ... 10 Technical Description ... 12 System fault finding ... 13 Explanation of Symbols ... 13 Conditions for Transport & Storage ... 14 Service Information... 14 Repair Information ... 14 Guarantee and Liability... 14

SECTION 1: IMPORTANT SAFETY INSTRUCTIONS 1.

2.

3.

4.

SAVE THESE INSTRUCTIONS - This manual contains important safety and operating instructions for the CSB-100 cast cutter, CB-100 battery and BC100 battery charger. Do not attempt to use the equipment until all the instructions and cautionary markings on the cast cutter, battery and battery charger, have been studied and understood. CAUTION - To reduce risk of injury, charge only De Soutter type CB-100 rechargeable batteries with the BC-100 battery charger. Other types of batteries may burst causing personal injury and damage Failure to follow these instructions may result in serious injury to the patient or operating staff.

Warnings & Safety Rules DANGER!: Possible explosion hazard if used in the presence of flammable anaesthetics. WARNING: Do not insert metal objects into the battery pack receptacles WARNING: Do not charge De Soutter Medical CB-100 battery pack with other chargers. WARNING: Do not sterilise the equipment. WARNING: Do not immerse the equipment. WARNING: Do not expose the equipment to rain or use near water. WARNING: Ensure that batteries are at room temperature before charging. WARNING: Do not attempt to dismantle or remove any parts of the battery pack or charger. WARNING: The Charger has been tested for electro-magnetic compatibility. However, if interference occurs that might cause undesirable operation, separate the components by moving further apart and, if possible, connect charger to a separate outlet. WARNING: Ensure that tool is switched off before inserting battery. WARNING: Do not attempt to charge any other battery other than the CB-100 battery with the BC-100 battery charger. Never permit untrained personnel to use this instrument system. Always check that the voltage stated on the charger identification plate corresponds with the electrical supply. Always inspect all equipment and accessories before use. Do not use suspect, damaged or worn equipment. Always disconnect the battery charger from the electrical supply when cleaning, or when not in use. Always ensure batteries are correctly connected to the cast cutter before use. Only use sharp cutting accessories Always set turn the CSB-100 cast cutter off when changing accessories or when not in use. Always use eye protection when cutting to prevent injury from flying debris. 3

Do not allow loose articles to be caught by the moving parts of the instrument. Never drop the instrument or it’s accessories; always handle with extreme care. Always use De Soutter Medical approved accessories. Only clean the equipment as directed in these Operating Instructions. Follow local recommendations for the avoidance of possible hand-arm vibration damage. The CSB-100 cast cutter can produce a HAV weighted vibration level of approximately 7.9ms-2 when the used with the supplied blade (part No. 6250). The HAV weighted vibration level will reduce if a smaller blade is used.

Environmental Conditions For Use Temperature: Relative Humidity:

0ºC to +30ºC 90% maximum.

Recommended Duty Cycle In order to reduce the risk of excessive and undesirable temperature rise of the handpiece it is recommended that the following duty cycle is applied. A usage/cooling ratio of 1 to 3 is recommended with a maximum continuous cutting time of 4 minutes. (i.e. if the tool is used for 1 minute it should be allowed to rest for at least 4 minutes, if it is used for 3 minutes it should be allowed to rest for at least 12 minutes).

4

SECTION 2: GENERAL INSTRUCTIONS Product Description The De Soutter Medical CSB-100 cordless cast cutter is designed for the safe removal of surgical casts or for the safe removal of crash helmets by accident and emergency personnel. The saw is powered by a rechargeable battery pack, and is supplied with one battery, battery charger and carry case. The CSB-100-A Cast Saw System Comprises: •

CSB-100

Cast Saw Handpiece

•

CB-100

Battery Pack

•

BC-100

Battery Charger

Mains Supply The BC-100 battery charger is supplied with mains plug adapters for UK, Euro, USA/Japan and Australia. Refer to section 3 for instructions on fitting the desired plug adapter to the battery charger.

Maintenance And Cleaning The system should be visually checked at each use for each of the following: •

Excessive build up of plaster dust.

•

The blade for wear.

•

The blade retainer for tightness.

Never use any equipment you suspect to be damaged.

Cleaning Brush all debris from the ventilation slots. Use suitable disinfecting and cleaning materials as per local decontamination guidelines.

5

SECTION 3: SYSTEM ASSEMBLY & OPERATION Setting Up The BC-100 Battery Charger Before using the BC-100 charger the correct mains plug adapter needs to be fitted. Slide the desired mains plug adapter into the bottom of the charger until it clicks into place as shown in the illustrations below. The battery charger is now ready for use.

Charging The CB-100 Battery / Charge Indicator Lights With the charger plugged into the mains supply socket connect the battery adapter to the CB-100 battery until it clips into place, as shown in the illustration below.

Turn on the battery charger at the mains supply socket and the charging sequence will commence, this will take up to 3.5 hours depending on the amount of residual charge in the battery pack. The indicator light describes the charge status as follows:

6

Indicator Light (In Sequence)

Status

Permanent Yellow Slow Yellow Flash Fast Green Flash Slow Green Flash Fast Yellow Flash

Charger on standby Pre Charge Rapid Charge Maintain Charge Error – Battery failed charging cycle, re-connect the charger plug to the battery. If the battery continues to fail after 3 attempts dispose of battery pack in accordance with disposal instructions. Ready – Battery is charged and ready for use. Wait – The battery is too hot, when the battery reaches normal temperature charging will commence. Charger turned off at mains supply socket.

Permanent Green Alternate Green and Yellow Flash No Light

When the battery is fully charged and ready for use (shown by a permanent green light) turn the charger off at the mains supply socket. Disconnect the battery adapter from the battery by depressing the battery catch and sliding the adapter off the battery. Do Not leave the battery adapter connected to the battery when the charger is switched off or disconnected from the mains supply. Battery Pack Disposal Rechargeable batteries contain substances that may be harmful and must be disposed of responsibly and safely. Do not dispose of them by throwing them into a fire or into water, as they may explode. Dispose of them either by returning them to your De Soutter Medical Distributor or by taking them to a proper refuse depot. Battery Care Guidance The performance and life of the battery packs can be considerably enhanced by the following measures: •

New batteries take some time to reach full performance. Battery packs achieve peak performance after approximately six charge/ discharge cycles. A run time of approximately 20 minutes can be expected from a fully charged battery.

•

Do NOT leave the battery adapter connected to the battery when the charger is switched off.

•

Do NOT use battery packs whilst still warm from charging. Allow adequate time for cooling prior to use.

7

Battery Pack Connection To Cast Cutter Insert the battery pack into the cast cutter until the catch clicks into place as shown in the illustration below.

Battery Pack Removal From Cast Cutter Depress the catch and slide the battery pack out from the cast cutter until it is fully disengaged, as shown in the illustration below.

CSB-100 Cast Cutter Controls The On/Off switch is located on the top of the saw, slide the switch forward to turn the saw on and slide the switch backwards to turn the saw off.

8

Saw Blade Assembly • • • •

Ensure the cast cutter is turned off. Remove the clamp screw using the hexagon wrench provided. Attach the blade of choice to the cast cutter output shaft. Refit the clamp screw and tighten using the hexagon wrench provided.

Saw Blade Removal • • •

Ensure the cast cutter is turned off. Remove the clamp screw using the hexagon wrench provided. Remove blade.

Always check the condition of the blade before use. The circular type saw blades may be repositioned up to five times, therefore always presenting an unused section of blade. Cutting Technique Before use, the operator should handle the saw and determine the most convenient grip position. Do Not exert excessive working pressure - allow the blade to cut at it’s own rate. Excessive pressure will overload the motor, without increasing cutting efficiency, and will reduce the output capacity of the battery. CAUTION: Excessive cutting pressure will also cause the blade to overheat which may result in injury to the patient. Likewise badly worn blades will generate excessive heat therefore the blades should be inspected and replaced regularly. A new or repositioned blade will improve cutting efficiency, reduce vibration and temperature of the blade when cutting. Make the first cut both downwards and slightly sideways, at approximately 30 degrees, in order to keep one side of the blade out of contact with the cast. This will allow the operator a greater sense of feel when the blade breaks through. After the first cut, all cuts should be made straight down into the cast. The cutter should be lifted slightly and moved sideways; the second cut can then be taken straight down, the operator feeling the break through quite easily. Cutting can then proceed in a series of downward cuts, lifting and moving sideways progressively. The blade may touch soft mobile tissue momentarily without harm under a light pressure. However it should never be permitted to be in contact with skin for any length of time

9

SECTION 4: TECHNICAL INFORMATION Product And Supplied Accessory Part Number Details Description Part No. CSB-100-A Cast Cutter System ... 1286774 Comprising: CSB-100 Cast Cutter ... 1286224 CB-100 Battery ... 15010 BC-100 Battery Charger ... 15020 Saw Blade ... 6250 Hexagon Wrench ... 204903 Carry Case ... 15030

Optional Accessories Description Part No. Plaster Shears ... 7680 Small Cast Spreaders ... 5120 Large Cast Spreaders ... 5130 Under Padding Scissors ... 15150

Saw Blades Part No. 1060

Dia. 80

3950

64

Type Circular PTFE Coated Circular TiN Coated

6230

44

Circular PTFE Coated

6240

50

Circular PTFE Coated

6250

64

Circular PTFE Coated

6260

80

Segment PTFE Coated

7310

64

Circular Diamond Coated

7320

80

Circular Diamond Coated

7960

64

Circular Stainless Steel

11120

76

Segment TiN Coated

11410

64

Circular Stainless Steel Ion Nitride Coated

14200

76

Segment Stainless Steel

15140

64

Segment Stainless Steel

10

Technical Description

CSB-100 Cast Cutter Oscillating speed Supply voltage Type of protection against electric shock Degree of protection against harmful ingress of liquids Mode of operation

CB-100 Battery Voltage Cell type Capacity

16,000 cpm 10.8Vdc Internally powered IPX0 – Ordinary Non continuous (See recommended duty cycle)

10.8Vdc Nickel metal hydride (Ni-MH) 2550mAh

BC-100 Battery Charger Supply voltage Supply frequency Current consumption (max) Type of protection against electric shock Degree of protection against harmful ingress of liquids Mode of operation Fuse

12

100-240V~ 50-60Hz 0.3A Class 2 – Double insulated IP40 Continuous T0.8A Internal. Not replaceable

Fault Finding See also battery charger section. Fault:

Possible Cause:

Remedy:

Battery charger indicator light does not illuminate

Check charger is switched on.

Check mains switch.

Charging light does not flash when battery pack is connected to battery charger

Faulty battery pack or battery pack excessively discharged.

Remove battery; leave for 24 hours and retry. If still unsuccessful, replace battery pack.

Battery pack not holding its charge

Faulty battery pack.

Replace battery pack

Battery pack becomes unusually hot during charging

Faulty battery pack.

Replace battery pack

Cast Cutter cuts out

Battery pack over temperature fuse tripped

Disconnect battery from cast cutter and allow battery to cool.

Saw cuts slowly

Blade is blunt

Adjust or replace the blade as necessary.

Faulty battery

Replace the battery

Flat battery

Charge the battery

Refer also to battery charger indicator light chart on page 7.

Explanation Of Symbols Refer to the Operating Instruction Manual

Do Not Immerse

Direct Current Dispose of in Accordance With Local Regulations.

Fuse

~

Alternating Current

Suitable for recycling

l

Power On

Class 2 type of protection against electric shock Double Insulated.

Serial number. First two

numerical digits indicate SN 09/00500 year of manufacture

13

O

Power Off

Conditions for Transport & Storage Temperature: Relative Humidity: Atmospheric Pressure:

-20ºC to +40ºC 90% maximum. 1.5 atmospheres maximum.

Service Information All powered instruments and attachments should be periodically checked and cleaned. Annual servicing is recommended for normal use. Due to the specialist techniques used in the manufacture and maintenance of De Soutter instruments, user servicing is not possible. Repair Information For service and repair please contact your nearest De Soutter Medical Authorised Service Centre. To return an instrument for repair: • Disinfect the equipment in accordance with the reprocessing instructions. • Record the serial number of the instrument being returned. Enclose a brief statement describing the reason for returning the instrument. • Enclose the purchase order number for the instrument if warranty is being claimed. It will be helpful to include a contact name. • Pack the instrument securely and send to the address below. Warning: All items returned for repair must be accompanied by a declaration of contamination status.

Guarantee & Liability De Soutter Medical guarantees all instruments, attachments and accessories to be free from defects in material and workmanship for one year from the date of purchase. De Soutter Medical is not liable by warranty or otherwise in the case of any of the following: • Abuse, misuse or use in other than a surgical environment; • Disassembly, alteration or unauthorised repair; • If the product has not been used in a reasonable manner and in full compliance with the written instructions. New battery packs are guaranteed for a period of six months from date of invoice. Non sterile consumables are guaranteed for their normal expected working life. This guarantee does not affect your Statutory Rights in accordance with 1999/44/EEC

14

United Kingdom De Soutter Medical Limited Halton Brook Business Park Weston Road Aston Clinton Bucks HP22 5WF United Kingdom Tel: +44 (0)1296 634 000 Fax: +44 (0)1296 634 033 Email: [email protected] Internet: http://www.de-soutter.com

Australia De Soutter Medical Australia Pty Ltd 2/12-14 Apollo Drive Hallam Victoria 3803 Australia Tel: +61 (0) 3 9702 4441 Fax: +61 (0) 3 9702 4484 Email: [email protected]

Österreich De Soutter Medical Austria Niederlassung Österreich Hofkirchnergasse 3/1/30 A-3400 Klosterneuburg Österreich Tel: +43 (0) 676 96 71 770 Fax: +43 (0) 2243 21 656 Email: [email protected]

Belgium De Soutter Medical Belgium In De Bruel 30 3620 Lanaken Belgium Tel: +32 (0) 89/47 15 37 Fax: +32 (0) 89/70 12 19 Email: [email protected]

France De Soutter Medical France 949 Avenue Park des Expositions 33260 La Teste de Buch France Tel: +33 (0) 5 56 54 89 36 Fax: +33 (0) 9 70 61 37 60 Email: [email protected]

Deutschland De Soutter Medical Germany Niederlassung Deutschland Kladenfloss D-66625 Nohfelden Germany

Italia De Soutter Medical Italia Palazzo Marco Polo II Girasole 20084 Lacchiarella Milano Italia Tel: +39 (0) 2 9009 4098 Fax: +39 (0) 2 9009 2673 Email: [email protected]

Tel: Fax: Email:

+49 (0) 68 52-99 12 46 +49 (0) 68 52-99 12 47 [email protected]

Ref: 2067 en_gb 1.2