Lafayette Instrument Company

JAMAR Hydrolic Model J00105 User Instructions Rel Feb 2004

User Instructions

8 Pages

Preview

Page 1

Model J00105

User’s Manual

1 Model J00105

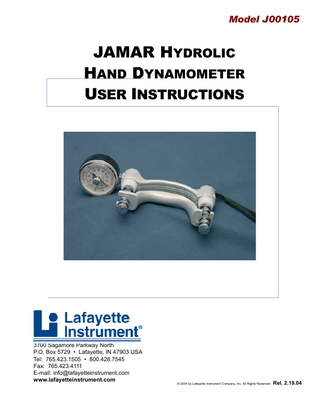

JAMAR HYDROLIC HAND DYNAMOMETER USER INSTRUCTIONS

3700 Sagamore Parkway North P.O. Box 5729 • Lafayette, IN 47903 USA Tel: 765.423.1505 • 800.428.7545 Fax: 765.423.4111 E-mail: [email protected] www.lafayetteinstrument.com

© 2004 by Lafayette Instrument Company, Inc. All Rights Reserved-

Fax: 765-423-4111 . www.lafayetteinstrument.com . E-mail: [email protected]

Rel. 2.19.04

1

2

Lafayette Instrument JAMAR Hydrolic Hand Dynamometer

Table of Contents: System Description Benefits Operation Table: Average Grip-Strength vs. Age Service Tips References Ordering Information

2

3 3 4 5 5 6 8

3700 Sagamore Parkway North . PO Box 5729 . Lafayette, IN 47903 USA . Ph: 765-423-1505

Model J00105

User’s Manual

3

DESCRIPTION: The JAMAR Adjustable Hand Dynamometer offers many features for both routine screening work and for evaluating hand trauma and disease. Dual-Scale Readout The JAMAR displays grip force in pounds and kilograms-200 pounds or 90 kilograms maximum reading. Peak-Hold Needle For convenience and easy recording, the JAMAR automatically retains the highest reading on a special peak-hold needle. This reading remains on the gauge until the examiner resets it. Accurate and Reproducible The JAMAR is isometric in use, with almost no perceptible motion of the handles, regardless of grip strength. The hand grasp is both comfortable and effective. These features combine to ensure accurate, reproducible results. Adjustable Handle To accommodate various size hands, the JAMAR handle adjusts to five grip positions: from 13/8 to 3-3/8 inches, in half-inch increments. Grip strength may also vary in an individual patient, depending on the size of the object being grasped. The adjustable handle allows therapists to quantify grip strength for different size objects.

BENEFITS: Detection of the Malingerer. For various reasons, some patients will be reluctant to exert maximum effort in grip force evaluation. Repeated tests after short rest periods will detect the malingering patient. To determine whether the patient is exerting maximum effort: a. Test grip in the usual manner, taking readings with the hand grip in all positions on the dynamometer. b. Test the normal hand, followed by the injured hand, allowing the subject to see readings. c. After about five minutes, repeat the test. Usually, if the subject has carried out the test will full effort, there will be less than 10% variation in results for various grip positions. But if he has exerted less-than-full-effort, there will be a larger, erratic variation, sometimes as much as 100% between the two tests.

Fax: 765-423-4111 . www.lafayetteinstrument.com . E-mail: [email protected]

3

4

Lafayette Instrument JAMAR Hydrolic Hand Dynamometer

OPERATION: When you use the JAMAR Hand Dynamometer, please remember that it is a precision instrument and its accuracy can be impaired by abuse. Have the subject use the wrist safety strap to minimize the chance of dropping the JAMAR. To use the dynamometer: 1.

Set the adjustable handle to the desired spacing. (Before moving the handle from one position to another, note that the handle clip is located at the lower (furthest) post from the gauge. If the handle is not replaced in the correct position, the readings will not be accurate.)

2.

Rotate the red peak-hold needle counterclockwise to 0.

3.

Let the subject arrange the instrument so that it fits in his hand comfortably. Ask him to squeeze with his maximum strength. The peak-hold needle will automatically record the highest force he has exerted.

4.

After the subject has used the instrument, record the reading.

5.

Reset the peak-hold needle to zero before recording new readings.

Suggested Standard Procedures 1.

Sit or stand comfortable

2.

Shoulder adducted and neutrally rotated

3.

Elbow flexed to 90 degrees

4.

Forearm in neutral position

5.

Wrist in neutral position

6.

Each test should be repeated 3 times

7.

Use the average as the recorded result

Suggested Interfering Factors The following factors have shown positive correlation with grip strength: 1. Weight 2. Hand width 3. Height 4. Mesomorphy

4

3700 Sagamore Parkway North . PO Box 5729 . Lafayette, IN 47903 USA . Ph: 765-423-1505

Model J00105

User’s Manual

5

Average Grip-Strength vs. Age

Note: The mean scores for individuals, aged 14-19 years, may be slightly low (0-10 lb lower than they should be) due to instrument error detected after the study. Fax: 765-423-4111 . www.lafayetteinstrument.com . E-mail: [email protected]

5

6

Lafayette Instrument JAMAR Hydrolic Hand Dynamometer

SERVICE TIPS: The JAMAR Dynamometer is designed to provide reliable service, with minimum maintenance, over a period of many years. To make sure the instrument is reading accurately, it’s a good idea to make a few checks, occasionally, as listed below. Posts Remove adjustable handle to check that each post moves up and down freely on its guide (the part that the post bears on), even when you exert pressure on the side of the post. About once a year, place a small amount of grease on the two guides. If excessive friction exists between the post and guide, return the dynamometer for service. Hydraulics To check the hydraulic mechanism, first remove the adjustable handle. While watching the top post, push down on the bottom post. Normally, both should travel about 1/8”, with top and bottom posts travelling in opposite directions. Travel less than 1/16”, indicates a probable leak in the hydraulic system, which requires service. Handle Grasp the instrument normally and look carefully at the way the forks of the adjustable handle are supported on the posts. Each fork should touch the post at approximately its midpoint. If this is not the case, return the instrument for adjustment. Peak-Hold Needle Check for excessive friction in the peak-hold assembly by turning the peak-hold knob counterclockwise. If the peak-hold needle deflects the gauge needle, return the gauge for service. If the peak-hold needle is knocked off its support pin, it can readily be repositioned. Unscrew the crystal and turn it upside down. Locate the brass pin in the center of the crystal (the pin is part of the chrome knob on the outside of the crystal). Locate the slot on the brass pin and place the peak-hold needle into this slot. Calibration The instrument is calibrated at the factory by loading it at the center with weight and making the appropriate adjustment in the gauge. It is not recommended that the user perform this operation, but rather the instrument be returned for calibration. The calibration should be checked on a regular, annual basis. If the instrument has been dropped or there is some particular reason to suspect that the calibration is in error, the instrument should be serviced immediately.

6

3700 Sagamore Parkway North . PO Box 5729 . Lafayette, IN 47903 USA . Ph: 765-423-1505

Model J00105

User’s Manual

7

REFERENCES: Everett, P., Sills, F., “The Relationship of Grip Strength to Stature, Somatotype Components, and Anthropometric Measurements of the Hand,” The Research Quarterly 23: 161-166, 1952. Ewing-Fess, E., “A Method for Checking Jamar Dynamometer Calibration,” Journal of Hand Therapy 1.1:28-32, 1987. Gill, D., Reddon, J., Renney, C., Stefanyk, W., “Hand Dynamometer: Effects of Trials and Session,” Perceptual and Motor Skills 61:195-198, 1985. Mathiowetz, V., Donahoe, L., Renells, C., “Effect of Elbow Position on Grip and Key Pinch Strength,” The Journal of Hand Surgery 10A: 694-697, 1985. Mathiowetz V., Dove, M., Kashman, N., Rogers, S., Volland, G., Weber, K., “Grip and Pinch Strength: Normative Data for Adults,” Arch Phys Med Rehabilitation 66: 69-72, 1985. Mathiowetz, V., Federman, S., Wiemer, D., “Grip and Pinch Strength: Norms for 6 to 19 Year Olds,” The American Journal of Occupational Thearpy 40: 705-711,1986. Mathiowetz, V., Weber, K., Volland, G., Kashman, N., “Reliability and Validity of Grip and Pinch Strength Evaluations,” The Journal of Hand Surgery, 9A: 22-26, 1984.

Fax: 765-423-4111 . www.lafayetteinstrument.com . E-mail: [email protected]

7

8

Lafayette Instrument JAMAR Hydrolic Hand Dynamometer

Ordering Information: All phone orders must be accompanied by a hard copy of your order. All must include the following information: 1) Complete billing and shipping addresses 2) Name and department of end user 3) Model number and description of desired item(s) 4) Quantity of each item desired 5) Purchase order number or method of payment 6) Telephone number DOMESTIC TERMS There is a $50 minimum order. Open accounts can be extended to most recognized educational institutions, hospitals and government agencies. Net amount due 30 days from the date of shipment. Enclose payment with the order; charge with VISA, MasterCard; or pay COD. We must have a hard copy of your order by mail or fax. Students, individuals and private companies may call for a credit application. INTERNATIONAL PAYMENT INFORMATION There is a $50 minimum order. Payment must be made in advance by: draft drawn on a major US bank; wire transfer to our account; charge with VISA, MasterCard; or confirmed irrevocable letter of credit. Proforma invoices will be provided upon request. RETURNS Equipment may not be returned without first receiving a Return Goods Authorization Number (RGA). When returning equipment for service, please call Lafayette Instrument to receive a RGA number. Your RGA number will be good for 30 days. Address the shipment to: Lafayette Instrument Company, 3700 Sagamore Parkway North, Lafayette, IN 47904, U.S.A. Shipments cannot be received at the PO Box. The items should be packed well, insured for full value, and returned along with a cover letter explaining the

malfunction. Please also state the name of the Lafayette Instrument representative authorizing the return. An estimate of repair will be given prior to completion ONLY if requested in your enclosed cover letter. We must have a hard copy of your purchase order by mail or fax, or repair work cannot commence. WARRANTY Lafayette Instrument guarantees its equipment against all defects in materials and workmanship to the ORIGINAL PURCHASER for a period of one (1) year from the date of shipment, unless otherwise stated. During this period, Lafayette Instrument will repair or replace, at its option, any equipment found to be defective in materials or workmanship. If a problem arises, please contact our office for prior authorization before returning the item. This warranty does not extend to damaged equipment resulting from alteration, misuse, negligence or abuse, normal wear or accident. In no event shall Lafayette Instrument be liable for incidental or consequential damages. There are no implied warranties or merchantability of fitness for a particular use, or of any other nature. Warranty period for repairs or used equipment purchased from Lafayette Instrument is 90 days. DAMAGED GOODS Damaged equipment should not be returned to Lafayette Instrument prior to thorough inspection. When a shipment arrives damaged, note damage on delivery bill and have the driver sign it to acknowledge the damage. Contact the delivery service, and they will file an insurance claim. When damage is not detected at the time of delivery, contact the carrier and request an inspection within 10 days of the original delivery. Please call the Lafayette Instrument Customer Service Department for a return authorization for repair or replacement of the damaged merchandise.

Lafayette Instrument Co. Europe 3700 Sagamore Parkway North 4 Park Road, Sileby, P.O. Box 5729 • Lafayette, IN 47903 USA Loughborough, Leics., LE12 7TJ. UK. Tel: 765.423.1505 • 800.428.7545 Tel: +44 (0)1509 817700 Fax: 765.423.4111 Fax: +44 (0)1509 817701 E-mail: [email protected] E-mail: [email protected] www.lafayetteinstrument.com 3700 Sagamore Parkway North . PO Box 5729 . Lafayette, IN 47903 USA . Ph: 765-423-1505

8