OLYMPUS

EVIS LUCERA GASTROINTESTINAL VIDEOSCOPE Reprocessing Manual

80 Pages

Preview

Page 1

INSTRUCTIONS

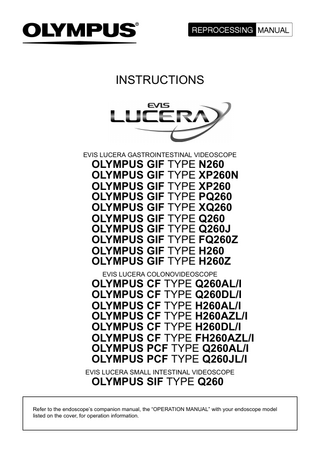

EVIS LUCERA GASTROINTESTINAL VIDEOSCOPE

OLYMPUS GIF TYPE N260 OLYMPUS GIF TYPE XP260N OLYMPUS GIF TYPE XP260 OLYMPUS GIF TYPE PQ260 OLYMPUS GIF TYPE XQ260 OLYMPUS GIF TYPE Q260 OLYMPUS GIF TYPE Q260J OLYMPUS GIF TYPE FQ260Z OLYMPUS GIF TYPE H260 OLYMPUS GIF TYPE H260Z EVIS LUCERA COLONOVIDEOSCOPE

OLYMPUS CF TYPE Q260AL/I OLYMPUS CF TYPE Q260DL/I OLYMPUS CF TYPE H260AL/I OLYMPUS CF TYPE H260AZL/I OLYMPUS CF TYPE H260DL/I OLYMPUS CF TYPE FH260AZL/I OLYMPUS PCF TYPE Q260AL/I OLYMPUS PCF TYPE Q260JL/I EVIS LUCERA SMALL INTESTINAL VIDEOSCOPE

OLYMPUS SIF TYPE Q260

Refer to the endoscope’s companion manual, the “OPERATION MANUAL” with your endoscope model listed on the cover, for operation information.

Contents

Contents Symbols...

1

Chapter 1

General Policy ...

2

1.1

Instructions...

2

1.2

Importance of cleaning, disinfection, and sterilization...

2

1.3

Signal words ...

3

1.4

Precautions ...

3

1.5

Reprocessing before the first use/reprocessing and storage after use ...

6

Compatible Reprocessing Methods and Chemical Agents ...

7

2.1

Compatibility summary...

7

2.2

Detergent solution...

9

2.3

Disinfectant solution...

10

2.4

Rinse water ...

10

2.5

Ethylene oxide gas sterilization...

11

2.6

Steam sterilization (autoclaving) of accessories ...

13

Cleaning, Disinfection, and Sterilization Procedures...

14

3.1

Required reprocessing equipment ...

14

3.2

Cleaning, disinfection, and sterilization procedures for the endoscope ...

24

3.3

Precleaning ...

25

3.4

Leakage testing...

31

3.5

Manual cleaning...

37

3.6

High-level disinfection ...

53

3.7

Rinsing after high-level disinfection ...

55

3.8

Sterilization ...

59

3.9

Cleaning, disinfection, and sterilization procedures for reusable parts and reprocessing equipment...

61

Chapter 4

Cleaning and Disinfection Equipment...

69

Chapter 5

Storage and Disposal...

71

5.1

Storage of the endoscope...

72

5.2

Storage of reusable parts and reprocessing equipment ...

73

5.3

Disposal ...

73

Chapter 2

Chapter 3

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

i

Contents

ii

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Symbols

Symbols The meaning(s) of the symbol(s) shown on the back cover of the instruction manual are as follows:

Manufacturer

Authorized representative in the European Community

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

1

Chapter 1 General Policy

Chapter 1 General Policy 1.1

1.2

Instructions •

This manual contains the cleaning, disinfection, and sterilization methods recommended by Olympus for the endoscopes listed on the front cover.

•

This instruction manual contains essential information on reprocessing these instruments safely and effectively.

•

Before reprocessing, thoroughly review the manuals of the reprocessing chemicals and all equipment that will be used and reprocess the equipment as instructed.

•

Note that the complete instruction manual set for this endoscope consists of this manual and the “OPERATION MANUAL” with your endoscope model listed on the cover. Both manuals accompanied the endoscope at shipment.

•

Keep this manual and all related manuals in a safe and accessible location.

•

If you have any questions or comments about any information in this manual, or if a problem that cannot be solved occurs while reprocessing, contact Olympus.

Importance of cleaning, disinfection, and sterilization The medical literature reports incidents of cross-contamination resulting from improper cleaning, disinfection, or sterilization. It is strongly recommended that all individuals engaged in reprocessing closely observe all instructions given in this manual and the manuals of all ancillary equipment, and have a thorough understanding of the following items:

2

•

Professional health and safety criteria of your hospital

•

Individual cleaning, disinfection, and sterilization protocols

•

Structure and handling of endoscopic equipment

•

Appropriate handling of chemicals

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 1 General Policy

For the types, conditions, and method of cleaning, disinfection, and sterilization to be adopted, refer to your hospital’s reprocessing policies and professional organization guidelines.

1.3

Signal words The following signal words are used throughout this manual:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices or potential equipment damage.

Indicates additional helpful information.

1.4

Precautions •

Failure to properly clean and high-level disinfect or sterilize endoscopic equipment after each procedure may compromise patient safety. To minimize the risk of transmitting diseases from one patient to another, after each procedure the endoscope and its ancillary equipment must undergo thorough manual cleaning followed by high-level disinfection or sterilization as described in Chapter 3, “Cleaning, Disinfection, and Sterilization Procedures”. Reprocess not only the external surface of the endoscope but also all channels.

•

ALL channels of the endoscope, including the auxiliary water channel (where existing), MUST be cleaned and high-level disinfected or sterilized during EVERY reprocessing cycle, even if the channels were not used during the previous patient procedure. Otherwise, insufficient cleaning and disinfection or sterilization of the endoscope may pose an infection control risk to the patient and/or operators performing the next procedure with the endoscope.

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

3

Chapter 1 General Policy

4

•

If the endoscope is not cleaned meticulously, effective disinfection or sterilization may not be possible. Clean the endoscope and accessories thoroughly before disinfection or sterilization to remove microorganisms and organic material that could reduce the efficacy of disinfection or sterilization.

•

Olympus only confirms validation of the endoscope reprocessors it recommends. When using an endoscope reprocessor that is not recommended by Olympus, the manufacturer of the endoscope reprocessor is responsible for validating compatibility of the reprocessor with the endoscope models listed in its instruction manual.

•

Before using an endoscope reprocessor, confirm that it is capable of reprocessing the endoscope, including all channels. If you are uncertain as to the ability of your endoscope reprocessor to clean and high-level disinfect the endoscope, including all channels, contact the endoscope reprocessor’s manufacturer for specific instructions and/or information on connectors. Insufficient cleaning and disinfection or sterilization of the endoscope may pose an infection control risk to the patient and/or operators performing the next procedure with the endoscope.

•

Patient debris and reprocessing chemicals are hazardous. Wear personal protective equipment to guard against dangerous chemicals and potentially infectious material. During cleaning and disinfection or sterilization, wear appropriate personal protective equipment, such as eyewear, face mask, moisture-resistant clothing, and chemical-resistant gloves that fit properly and are long enough so that your skin is not exposed. Always remove contaminated personal protective equipment before leaving the reprocessing area.

•

Thoroughly rinse off the disinfectant solution. Rinse the external surface of the endoscope, all channels, and the reprocessing equipment thoroughly with water to remove any disinfectant solution residue.

•

The disinfection/sterilization room must be adequately ventilated. Adequate ventilation protects against the buildup of toxic chemical fumes.

•

Store alcohol in an airtight container. Alcohol stored in an open container is a fire hazard and will result in a loss of efficacy due to evaporation.

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 1 General Policy

•

Be sure to perform a leakage test on the endoscope prior to manual cleaning. Do not use the endoscope if a leak is detected. Use of an endoscope with a leak may cause a sudden loss of the endoscopic image, damage to the bending mechanism, or other malfunctions.

•

Prior to each procedure, confirm that the endoscope has undergone proper cleaning, disinfection, and sterilization. If it is determined that the endoscope has not been properly reprocessed, reprocess it again following the instructions given in this manual.

•

With the cleaning, disinfection, and sterilization methods stated in this instruction manual, prions, which are the pathogenic agent of Creutzfeldt-Jakob disease (CJD) cannot be destroyed or inactivated. When using this instrument on a patient with CJD or variant Creutzfeldt-Jakob disease (vCJD), be sure to use this product for such patient only and/or immediately dispose of this product after use in an appropriate manner. For methods to handle CJD, please follow the respective guidelines in your country.

•

This instrument may not be durable, or may not have sufficient durability against the respective methods stated in the guidelines of each country for removing or inactivating prions. For information on the durability against each method, please contact Olympus. If cleaning, disinfection, and sterilization methods not stated in this instruction manual are performed, Olympus cannot guarantee the effectiveness, safety and durability of this instrument. Be sure to confirm that there is no irregularity before use, and use under responsibility of a physician. Do not use if any irregularity is observed.

•

When aerating or irrigating the endoscope channels, the air or water pressure must not exceed 0.5 MPa (5 kgf/cm2, 71 psig). Higher pressures may cause damage to the endoscope.

•

When reprocessing an endoscope that has a flexibility adjustment mechanism, make sure that the insertion section is set to its most flexible condition (indicated by the “z” mark on the flexibility adjustment ring). If the endoscope is cleaned and disinfected or sterilized while the insertion section is too rigid, the endoscope may be damaged (for endoscopes with flexibility adjustment only).

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

5

Chapter 1 General Policy

•

When reprocessing an endoscope, confirm that the water-resistant cap is securely attached to the endoscope connector, the zoom connector (for CF-H260AZL/I, CF-FH260AZL/I only) and the UPD scope connector (for CF-Q260DL/I, CF-H260DL/I only) before immersing the endoscope in reprocessing fluids. If the water-resistant cap is not securely attached, water, detergent solution, and/or disinfectant solution could enter the endoscope and damage the equipment. The compatible water-resistant caps are shown in Table 1.1.

Endoscope

Water-resistant cap

CF-H260AZL/I, CF-FH260AZL/I

MH-553 and MAJ-583

CF-Q260DL/I, CF-H260DL/I

MH-553 and MAJ-942

Others

MH-553

Table 1.1

1.5

Reprocessing before the first use/reprocessing and storage after use This instrument was not cleaned, disinfected, or sterilized before shipment. Before using this instrument for the first time, reprocess it according to the instructions given in this manual. After using this instrument, reprocess and store it according to the instructions given in this manual. Improper and/or incomplete reprocessing or storage can pose an infection control risk, cause equipment damage, or reduce performance.

6

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

Chapter 2 Compatible Reprocessing Methods and Chemical Agents 2.1

Compatibility summary Olympus endoscopic equipment is compatible with several methods of reprocessing. However, certain components and accessories are not compatible with some methods, which can cause equipment damage. For appropriate reprocessing methods, refer to Table 2.1 below, the recommendations of your infection control committee, and all national and local hospital guidelines and policies.

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

7

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

.

Steam sterilization (autoclaving) Ethylene oxide gas sterilization (gas mixture 20% ethylene oxide gas/80% CO2) Ethylene oxide gas sterilization (100% ethylene oxide gas) ACECIDE disinfectant solution∗3 (use OER-A, OER-AW) 2 – 3.5% glutaraldehyde 70% ethyl or isopropyl alcohol Detergent solution Ultrasonic cleaning Endoscope

∗1

Water-resistant cap (MH-553) Chain for water-resistant cap (MAJ-1119) Water-resistant cap (MAJ-583, MAJ-942)

∗2

∗2

Channel cleaning brush (BW-20T) Channel-opening cleaning brush (MH-507) Channel cleaning brush (BW-9Y) Air/water valve (MH-438) Suction valve (MH-443) Biopsy valve (MB-358) Channel plug (MH-944) Injection tube (MH-946) AW channel cleaning adapter (MH-948) Suction cleaning adapter (MH-856) Mouthpiece (MB-142, MA-474) Auxiliary water tube (MAJ-855) compatible

not compatible

Table 2.1

8

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

∗1 The endoscope is only compatible with ultrasonic cleaning as performed in an endoscope reprocessor such as OER, OER-A, OER-AW (OER, OER-A, OER-AW are not available in some areas). ∗2 The water-resistant cap and the chain for water-resistant cap can only be ultrasonically cleaned if connected to the endoscope that is being cleaned in an endoscope reprocessor with an ultrasonic cleaning phase. ∗3 ACECIDE disinfectant solution is exclusively for OER-A, OER-AW.

Alcohol is not a sterilant or high-level disinfectant.

•

EndoTherapy accessories that are marked by the words “AUTOCLAVE” or “AUTOCLAVABLE”, or accessories with a green model reference label are compatible with steam sterilization (autoclaving).

•

The endoscope is compatible with some endoscope reprocessors such as the ETD∗1 system distributed by Olympus. Refer to the respective instruction manual for details on operation. For any other details, please contact Olympus. ∗1 This product may not be available in some areas.

2.2

Detergent solution Use a medical-grade, low-foaming, neutral pH detergent or enzymatic detergent and follow the manufacturer’s dilution and temperature recommendations. Contact Olympus for the names of specific brands of detergent solutions that have been tested for compatibility with the endoscope. Do not reuse detergent solutions.

Excessive detergent foaming can prevent fluid from adequately contacting the interior of the channels.

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

9

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

2.3

Disinfectant solution In the U.S., agents used to achieve high-level disinfection are defined as liquid chemical germicides registered with the U.S. Food and Drug Administration as “sterilant/disinfectants” that are used according to the time, temperature, and dilution recommended by the disinfectant manufacturer for achieving high-level disinfection. These conditions usually coincide with those recommended by the disinfectant manufacturer for 100% kill of mycobacterium tuberculosis. In general, 2 – 3.5% glutaraldehyde solutions, when used according to the manufacturer’s instructions for achieving high-level disinfection, are compatible with Olympus endoscopes. If the disinfectant solution is reused, routinely check its efficacy with a test strip according to the manufacturer’s recommendations. Do not use solutions beyond their expiration date.

For further information regarding the compatibility of glutaraldehyde-based or nonglutaraldehyde-based disinfectant solutions, contact your local Olympus organization.

2.4

Rinse water Once removed from disinfectant solution, the instrument must be thoroughly rinsed with sterile water to remove any disinfectant residue. If sterile water is not available, clean, potable tap water or water that has been processed (e.g., filtered) to improve its microbiological quality may be used. When nonsterile water is used after disinfection, wipe the endoscope and flush the channels with 70% ethyl or isopropyl alcohol, then air-dry all internal channels to inhibit the growth of bacteria. Do not reuse rinse water.

10

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

2.5

Ethylene oxide gas sterilization The instruments and other accessories listed as compatible with ethylene oxide gas sterilization in Table 2.1 on page 8 can be sterilized by ethylene oxide gas and aerated within the parameters given in Tables 2.2 and 2.3. When performing ethylene oxide gas sterilization, follow the cleaning, disinfection, and sterilization protocols of your hospital and the instruction manuals for the sterilization equipment.

•

Before sterilization, the instrument must be thoroughly cleaned and dried. Residual moisture may inhibit sterilization.

•

The results of sterilization depend on various factors, such as how the sterilized instrument was packed, or the positioning, method of placing, and loading the instrument in the sterilization device. Please verify that the conditions necessary to achieve sterilization were adequate using biological or chemical indicators. Also follow the guidelines for sterilization issued by medical administrative authorities, public organizations, or the infection management sections at each medical facility, as well as the instruction manual for the sterilization device.

•

All instruments must be properly aerated following ethylene oxide gas sterilization to remove toxic ethylene oxide residuals.

•

Disconnect the water-resistant caps from the endoscope connector, the zoom connector (for CF-H260AZL/I, CF-FH260AZL/I only) and the UPD scope connector (for CF-Q260DL/I, CF-H260DL/I only) before ethylene oxide gas sterilization. If the water-resistant caps are attached during ethylene oxide gas sterilization, the air inside the endoscope will expand and rupture the covering of the bending section and/or damage the angulation mechanism.

•

Exceeding the recommended parameters may cause equipment damage (see Tables 2.2 and 2.3).

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

11

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

Parameters for 100% ethylene oxide gas sterilization cycles Process phase Sterilization

Parameter

Value

Temperature

55°C (130°F)

Vacuum

0.05 – 0.07 MPa

(Absolute pressure) (7.25 – 10.15 psia)

Aeration

Relative humidity

50 – 80%

Ethylene oxide gas concentration

0.735 – 0.740 mg/cm3 (735 – 740 mg/L)

Exposure time

60 minutes

Minimum aeration parameters

12 hours in an aeration chamber at 50 – 57° (122 – 135°F) or 7 days at room temperature

Table 2.2

Parameters for 20% ethylene oxide gas/80% CO2 gas sterilization cycles Process phase Sterilization

Aeration

Parameter

Value

Temperature

57°C (135°F)

Relative pressure

0.1 – 0.17 MPa

Relative humidity

55%

Ethylene oxide gas

0.6 – 0.7 mg/cm3

concentration

(600 – 700 mg/L)

Exposure time

105 minutes

Minimum aeration

12 hours in an aeration chamber

parameters

at 50 – 57°C (122 – 135°F) or 7 days at room temperature

Table 2.3

12

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 2 Compatible Reprocessing Methods and Chemical Agents

2.6

Steam sterilization (autoclaving) of accessories The accessories listed as compatible with steam sterilization (autoclaving) in Table 2.1 on page 8 can be sterilized by steam within the parameters given in Table 2.4. When steam sterilizing, follow the cleaning, disinfection, and sterilization protocols of your hospital as well as the instructions provided by the manufacturer of your sterilization equipment.

The results of sterilization depend on various factors, such as how the sterilized instrument was packed, or the positioning, method of placing, and loading the instrument in the sterilization device. Please verify that the conditions necessary to achieve sterilization were adequate using biological or chemical indicators. Also follow the guidelines for sterilization issued by medical administrative authorities, public organizations, or the infection management sections at each medical facility, as well as the instruction manual for the sterilization device.

•

Do not steam sterilize the endoscope. Steam sterilization (autoclaving) will severely damage the endoscope.

•

Do not exceed a setting temperature of 134°C (273°F), equivalent to a maximum temperature of 137°C (279°F), nor an exposure time greater than 20 minutes. Otherwise, the instrument may be damaged.

Process Prevacuum

Table 2.4

Parameters Temperature

132 – 134°C (270 – 274°F)

Exposure time

5 minutes

Steam sterilization (autoclaving) exposure parameters

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

13

Chapter 3 Cleaning, Disinfection, and Sterilization Procedures

Chapter 3 Cleaning, Disinfection, and Sterilization Procedures ALL channels of the endoscope, including the auxiliary water channel (where existing), MUST be cleaned and high-level disinfected or sterilized during EVERY reprocessing cycle, even if the channels were not used during the previous patient procedure. Otherwise, insufficient cleaning and disinfection or sterilization of the endoscope may pose an infection control risk to the patient and/or operators performing the next procedure with the endoscope.

3.1

•

Do not coil the endoscope’s insertion tube or universal cord with a diameter of less than 12 cm. Doing so may damage the endoscope.

•

For proper reprocessing results, do not coil the insertion section or the universal cord with a diameter of less than 40 cm. If the diameter is less than 40 cm, it will be difficult to insert the channel cleaning brush (BW-20T, BW-9Y).

Required reprocessing equipment Preparation of the equipment Prior to cleaning, disinfection, or sterilization, prepare the equipment shown in Figure 3.1.

Use basins that are at least 40 cm by 40 cm (16” by 16”) in size and deep enough to completely immerse the endoscope.

14

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 3 Cleaning, Disinfection, and Sterilization Procedures

Water-resistant cap (MH-553)

Channel cleaning brush (BW-20T, except SIF-Q260) (BW-9Y, for SIF-Q260 only)

Channel-opening cleaning brush (MH-507)

Suction pump (KV-4, KV-5, SSU-2) (sold separately)

Injection tube (MH-946)

AW channel cleaning adapter (MH-948)

Maintenance unit (MU-1) (sold separately)

Channel plug (MH-944)

Leakage tester (MB-155) (sold separately)

Light source (CLV-260SL/260NBI∗1/260/U40/U20) (sold separately) Water-resistant cap (MAJ-583, for CF-H260AZL/I, CF-FH260AZL/I only)

Auxiliary water tube (MAJ-855, for endoscopes with auxiliary water feeding only)

Water-resistant cap (MAJ-942, for CF-Q260DL/I, CF-H260DL/I only)

Suction cleaning adapter (MH-856)

• Personal protective equipment

• Sterile water

• 500 cm3 (500 ml) containers

• 70% ethyl or isopropyl alcohol

• Large basins with tight-fitting lids∗2

• Soft brush

• Small basins with tight-fitting lids

• Clean, lint-free cloths

(size: 25 (W) × 10 (H) × 25 (D) cm or more) • Clean water

• Sterile, lint-free cloths

• Detergent solution

• Sterile cotton swabs

• Disinfectant solution

• 30 cm3 (30 ml) syringe

∗1 CLV-260NBI may not be available in some areas. ∗2 Use basins that are at least 40 cm by 40 cm (16” by 16”) in size and deep enough to completely immerse the endoscope. Figure 3.1 EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

15

Chapter 3 Cleaning, Disinfection, and Sterilization Procedures

Reprocessing equipment parts and functions For inspection of equipment other than that mentioned below, refer to the instruction manual for the equipment being used.

Water-resistant cap (MH-553) The water-resistant cap is attached to the electrical connector on the endoscope to protect the connector from water penetration during reprocessing. For leakage testing, the venting connector on the water-resistant cap must be connected to the leakage tester (see Figure 3.2).

Groove Venting connector Seal

Figure 3.2

Water-resistant cap (MAJ-583, for CF-H260AZL/I, CF-FH260AZL/I only) The water-resistant cap (MAJ-583) is attached to the zoom connector of the endoscope to protect the connector from water penetration during reprocessing. The water-resistant cap is connected to the endoscope by a chain (see Figure 3.3).

Chain

Seal

Screw

Figure 3.3

16

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

Chapter 3 Cleaning, Disinfection, and Sterilization Procedures

Water-resistant cap (MAJ-942, for CF-Q260DL/I, CF-H260DL/I only) The water-resistant cap (MAJ-942) is attached to the UPD connector of the endoscope to protect the connector from water penetration during reprocessing. The water-resistant cap is connected to the endoscope by a chain (see Figure 3.4).

Chain

Seal

Screw

Figure 3.4

Channel plug (MH-944) The channel plug is used to plug the openings of the instrument channel port and the air/water and suction cylinders during cleaning (see Figure 3.5).

Biopsy valve cap

Cylinder plug

Figure 3.5

EVIS LUCERA GIF/CF/PCF/SIF TYPE 260 Series REPROCESSING MANUAL

17