W & H Dentalwerk

Implantmed SI-923 and SI-915 Instructions For Use Rev 005 May 2010

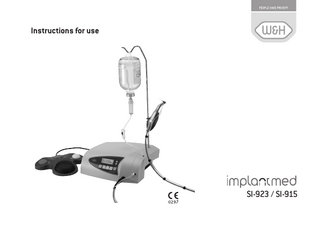

Instructions for Use

52 Pages

Preview

Page 1

Instructions for use

SI-923 / SI-915

Contents 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18.

W&H Symbols ...4 – 5 Introduction...6 – 7 Electromagnetic compatibility (EMC) ...8 Unpacking ...9 Equipment supplied ...10 Safety notes ...11 – 14 Description of front panel ...15 Description of rear panel ...16 Description of motor with cable ...17 Starting operation – General...18 Starting operation – Foot control...19 – 22 Factory settings ...23 – 25 Control unit operation...26 – 29 Error messages...30 Hygienic maintenance ...31 – 35 W&H Accessories ...36 – 38 Servicing ...39 – 40 Technical data ...41 – 42 Recycling and disposal...43 Certification of training ...45, 47 Letter of indemnity ...49 Authorized W&H service partner ...51 3

W&H Symbols Symbols in the Instructions for use

WARNING! (Risk of injury)

ATTENTION! (to prevent damage occurring)

General explanations, without risk to persons or objects

Thermo washer disinfectable

Sterilizable up to the stated temperature

W&H Service

Only for USA Caution: Federal law restricts this device to sale by or on the order of a dentist, physician or any other practitioner licensed by the law of the state in which he or she practices to use or order the use of the device.

4

W&H Symbols Symbols on the control unit (rear panel) Consult Instructions for use

Class II equipment

Date of manufacture

Electric fuse

Not suitable for intracardiac application – Type BF appliance

Do not dispose of with domestic waste

REF Catalogue number SN

Serial number

V

Supply voltage of the unit

AC

Alternating current

W

Electric power input of the unit

A

Supply current

Hz

Frequency of the alternating current

Foot switch

Data Matrix Code for product identificaction, e.g. in hygienic maintenance process Classification mark, that this product is in compliance with the American and Canadian safety requirements

rpm Revolutions per minute 5

1. Introduction For your safety and the safety of your patients These Instructions for Use explain how to use your W&H product. However, we must also warn against possible hazardous situations. Your safety, the safety of your team, and of course, the safety of your patients are of paramount importance to us.

It is therefore essential to read the safety notes on Pages 11 to 14.

Intended use Mechanical drive unit with coolant supply for transmission instruments with coupling system according to ISO 3964 (DIN 13.940). The equipment is a drive unit for use in dental surgery, implantology, maxillo-facial surgery and endodontics for treatment of dental hard tissue and mechanical rotating root canal preparation.

Qualifications of the user Only suitably qualified medical, technical and specialist trained staff may use the W&H dental surgical unit Implantmed. We have based our development and design of the Implantmed on the »physician« target group. 6

Introduction Production according to EU Directive EU Directive 93/42/EEC has been used as a basis in the design and manufacture of this medical product and this applies to the dental surgical units > Implantmed SI-915 and > Implantmed SI-923 in the condition as supplied by us. This declaration does not apply to non-specified fittings, mountings etc.

Responsibility of the manufacturer The manufacturer can only accept responsibility for the safety, reliability and performance of the Implantmed when there is compliance with the following directions: > The Implantmed must be used in accordance with these Instructions for Use. > The Implantmed has no components which can be repaired by the user. Assembly, modifications or repairs must only be undertaken by an authorized W&H service partner (see Page 51). > The electrical installation at the premises must comply with the regulations of ÖVE-EN 7 (»Installation of electrical equipment in rooms used for medical purposes«) or with the regulations applicable in your country. > Unauthorized opening of the equipment invalidates all claims under warranty and any other claims.

7

2. Electromagnetic compatibility (EMC) Notes on electromagnetic compatibility (EMC) Medical electrical equipment is subject to particular precautions with regards to EMC and must be installed and put into operation in accordance with the EMC notes included. W&H guarantees the compliance of the device with the EMC requirements only when used with original W&H accessories and spare parts. The use of other accessories / other spare parts can lead to an increased emission of electromagnetic interference or to a reduced resistance against electromagnetic interference. You can find the current EMC manufacturer’s declaration on our website at http://wh.com/en_global/emc

HF communication equipment Do not use any portable and mobile HF communication equipment (e.g. mobile telephones) during operation. These may affect medical electrical equipment.

8

3. Unpacking ➊ Lift out insert with stand.

➍ Remove irrigation tubing set.

➋ Remove foot control

➎ Remove carton containing

and insert.

➌ Lift out insert with control unit.

motor, mains cable, motor support and instruments (optional).

W&H packaging is environmentally friendly and can be disposed of by industrial recycling companies. However, we recommend that you keep the original packaging.

9

4. Equipment supplied Control unit ❍ green REF 04708900 (230 V) ❍ blue REF 04801300 (230 V) ❍ Foot control S-NU REF 04785700 ❍ Motor with 1.8 m cable including 5 clips, REF 04720000 ❍ Mains cable REF 01343700 (Europa) ❍ Motor support REF 04735700 ❍ Stand REF 04005900 ❍ Locking pins REF 04006800 (2 pcs) ❍ Irrigation tubing set REF 436360 (3 pcs, disposable) Alternative specification: Control unit ❍ green REF 04691400 (115 V) ❍ blue REF 04801200 (115 V) ❍ Mains cable REF 02821400 (USA, CAN, J) / REF 03212700 (UK, IRL) / REF 02909300 (AUS, NZ) / REF 04280600 (CH) ❍ Foot control S-N1 REF 05046200 Optional accessories: ❍ W&H instruments ❍ Motor protective cover REF 04032600 ❍ Sterilization cassette REF 04013500 ❍ Transportation case REF 04013600 ❍ Trolley white REF 04541900 / REF 04542100 ❍ Trolley, stainless steel REF 04042600 10

5. Safety notes Please ensure that you carry out the following instructions > Only fit the handpieces when the motor is at a complete standstill. > Never touch rotary instruments which are still rotating. > Never touch the chuck mechanism of straight and contra-angle handpieces while they are still running. > Always ensure correct operating conditions and that sufficient and adequate cooling is delivered. > Avoid overheating at the treatment site.

Use only suitable and serviceable tools Ensure that you comply with the manufacturer's instructions for surgical straight and contra-angle handpieces with respect to maximum speed, maximum torque, forward and reverse movement.

Inappropriate use Improper use, in addition to incorrect assembly, installation, modification or repairs of the Implantmed or non-compliance with our instructions invalidates all claims under warranty and any other claims.

Cardiac pacemaker function Use of the Implantmed involves the generation of magnetic fields, which are below the interference threshold limit according to EN 50061 Ad1. Even under adverse conditions, there is no likelihood of serious harm to the patient. The Implantmed is designed for the intermittent operating mode S3 with an operating time of 4 minutes and a pause time of 10 minutes. 11

Safety notes Danger zones M and G In accordance with IEC 60601-1 / UL 60601-1, the control unit is not suitable for use in potentially explosive atmospheres or with potentially explosive mixtures of anaesthetic substances containing oxygen or nitrous oxide.

Control unit The control unit is classed as »conventional equipment« (closed equipment without protection against the ingress of water). The Implantmed Programs 4 and 5 are only designed to be used with the contra-angle handpieces WS-75 E/KM, WI-75 E/KM, WI-75 LED G and EB-79 approved by W&H. Use of other contra-angle handpieces may result in deviation from the indicated torques and is under the user’s responsibility. The specified transmission ratios for the Programs 1 to 5 must always be considered.

Motor and foot control The motor and foot control are approved for use in zone M (AP). Please note that at low speeds, it is more difficult to determine that the motor is running.

Automatic reverse drive ENDODONTICS If the file jams the motor automatically changes from forward drive to reverse drive and simultaneously an audible warning signal can be heard. If the file does not release within approx. 3 seconds, the motor switches off automatically. 12

Safety notes Mains cable Only connect to an earthed socket outlet.

Power failure In the event of a power failure, if the Implantmed is switched off, or when alternating between programs, the last values set are saved and re-activated on power-up.

System failure A total system failure of the Implantmed does not constitute a critical fault.

Intermittent operating mode S3 (4min/10min) When there is a current consumption of max. 0,8 A for SI-923 and 1,6 A for SI-915 (with pump switched on), the permissible relative load time is 4 minutes to 10 minutes pause time.

13

Safety notes Coolant The Implantmed is designed for use with physiological saline solution. Use only suitable irrigation fluids and comply with the medical data and instructions from the manufacturer. Use the W&H irrigation tubing set or accessories approved by W&H. Coolant bottle or coolant bag can be obtained from a pharmacist.

Sterility of irrigation tubing set Sterile irrigation tubing sets are supplied with the equipment. These irrigation tubings are disposable articles and must be thrown away after each treatment! Please note the expiry date and the relevant regulations for disposal of irrigation tubing.

Rotational energy Fast deceleration of the bur can, at times, cause the selected torque to be overloaded as a result of the rotational energy stored in the drive system. We therefore advise compliance with the individual manufacturer's instructions for use, particularly when adjusting superstructure screws. For safety reasons, these should be screwed in very carefully by hand, or by using a torque wrench. We would point out that adjusting these screws with an electric motor represents a potential risk as described above.

14

6. Description of front panel Pump arm

Program buttons IMPLANTOLOGIE

Stand holder

Display

20:1

1:1

P2

P1

P3

P4

OPEN Pump arm

Program button ENDODONTIE 2:1

Motor connection socket P5 15

7. Description of rear panel Stand holder

Connecting socket for foot control

Power socket

Power switch ON / OFF

Fuse holder with 2 fuses REF 04014700 (250 V – 1.25A slow-blow)

16

8. Description of motor with cable The motor may not be dismantled! The motor bearings are lubricated for life. No oil lubrication or other maintenance is necessary.

To prevent the instrument on the motor attachment from turning during transmission, the locking pin supplied can be pushed into the designated hole (see illustration). The locking pin can only be used in combination with straight and contra-angle handpieces that have corresponding holes.

Test run > Start the motor. > If you observe problems (e.g. vibrations, unusual noise, overheating, coolant supply failure or leakage), stop the motor immediately and contact an authorized W&H service partner (see Page 51). 17

9. Starting operation – General ➊ Connect the mains cable and

➍ Place the motor support on

foot control.

the stand and rotate it to fix in place.

➋ Connect the motor cable.

➎ Connect the irrigation tubing set.

Note the positioning! 1:1

1:1

20:1

20:1

2:1

2:1

> Open pump arm (a) a

> Fit the irrigation tubing set (b, c, d)

d

➌ Insert the stand. Note the positioning!

b

c

e

> Close pump arm (e)

1:1

20:1

2:1

18

10. Starting operation – Foot control S-NU

ORANGE Change program GREEN Pump

Implantology: Program 1 to 4 Endodontics: Endo mode E1 to E5

Implantology: ON / OFF Endodontics: not in operation

YELLOW Change motor direction Implantology and Endodontics: forward / reverse drive

BLACK Start motor Implantology: VARIABLE or ON / OFF (Factory setting = variable) Endodontics: ON / OFF (Factory setting = ON / OFF)

19

Starting operation – Foot control S-N1

ORANGE Change program Implantology: Program 1 to 4 Endodontics: Endo mode E1 to E5

GREEN Pumpe Implantology: ON / OFF Endodontics : not in operation

YELLOW Change motor direction Implantology and Endodontics: forward / reverse drive

GREY Start motor Implantology: VARIABLE or ON / OFF (Factory setting = variable) Endodontics: ON / OFF (Factory setting = ON / OFF)

20

Starting operation – Foot control S-NU and S-N1 Changing program IMPLANTOLOGY The Programs 1 – 4 can be selected in ascending sequence by operating the ORANGE button. When changing from Program 4 to Program 1, a longer confirmation signal is heard. With each program change, the motor direction is automatically set to forward operation.

Changing program ENDODONTICS The Endo mode E1 – E5 in Program 5 can be selected in ascending sequence by operating the ORANGE button. When changing from Endo mode E5 to Endo mode E1, a longer confirmation signal is heard. With each program change, the motor direction is automatically set to the last motor direction set in that program.

Pump ON / OFF Only when the motor is stationary can the pump be switched on or off by operating the GREEN button of the foot control. When pump operation is active, the pump symbol appears on the display.

Reverse operation You can switch between forward and reverse operation by pressing the YELLOW button. On selecting reverse operation, an audible signal can be heard and the selected Program button flashes. Before the motor starts in reverse operation, 3 audible warning signals are given.

21